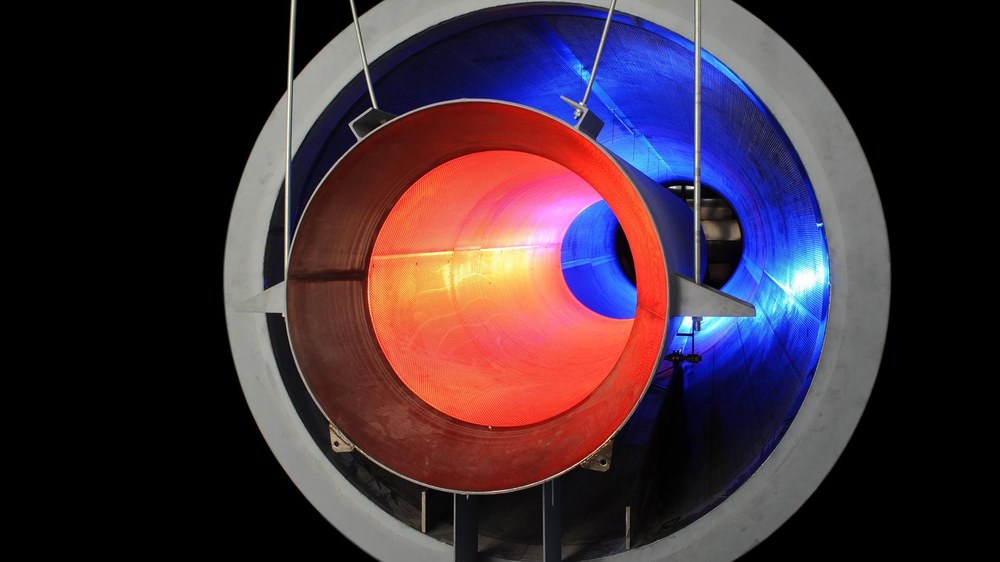

High-pressure Combustion Chamber Test Rig 1 (HBK1)

Researchers use this large-facility at the DLR Institute of Propulsion Technology in Cologne to investigate full-scale aircraft gas turbine burners under realistic operating conditions. The test rig enables independent control of the individual operating parameters for burners and combustion chambers.

Investigation of gas turbine burners under realistic conditions

This large-scale DLR facility forms the supply and operating environment for various measurement sections. These are designed for the investigation of full-scale gas turbine burners under realistic operating conditions. For instance, HBK1 is operated with both single burner combustion chambers, as well as with multi-burner sectors. In this regard, not only do all combustion chambers exhibit geometrical similarity to the original operating environment, the division of cooling, mixing and secondary air is also analogous to the actual engine combustion chamber.

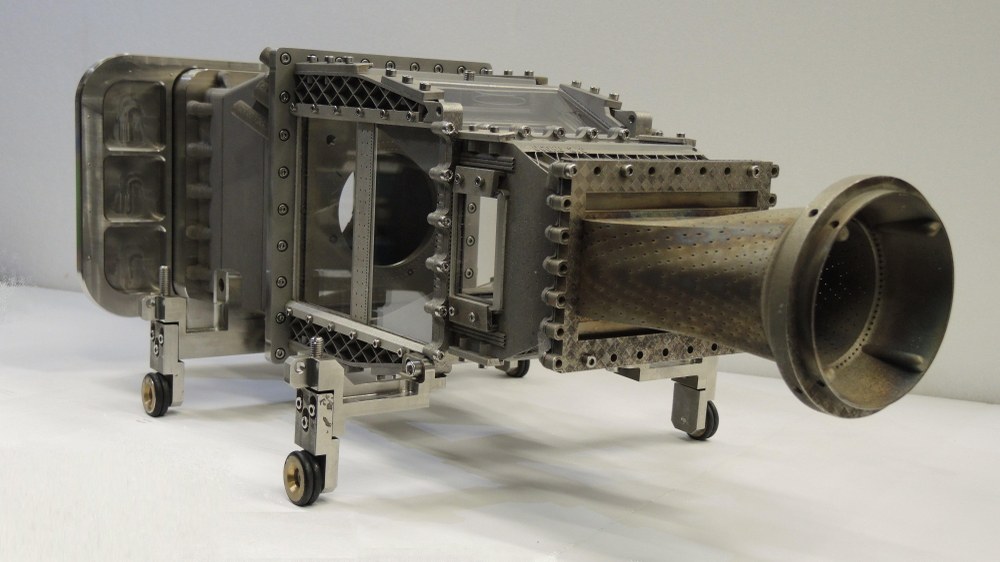

In addition, the combustion chambers provide full optical accessibility. This enables the use of optical measurement techniques to record the processes and interactions across all zones and areas of the combustion chamber, without influencing the reacting flow field. The independent control of air and fuel mass flows – as well as pressure – within HBK1 allows the attainment and control of a broad and comprehensive range of operating conditions, including off-design points. New technical innovations for the mitigation of pollution within the aviation sector can be investigated very quickly in a TRL-4 environment using HBK1. This is made possible by the installation of modular combustion chambers that are manufactured using Selective Laser Melting (SLM).