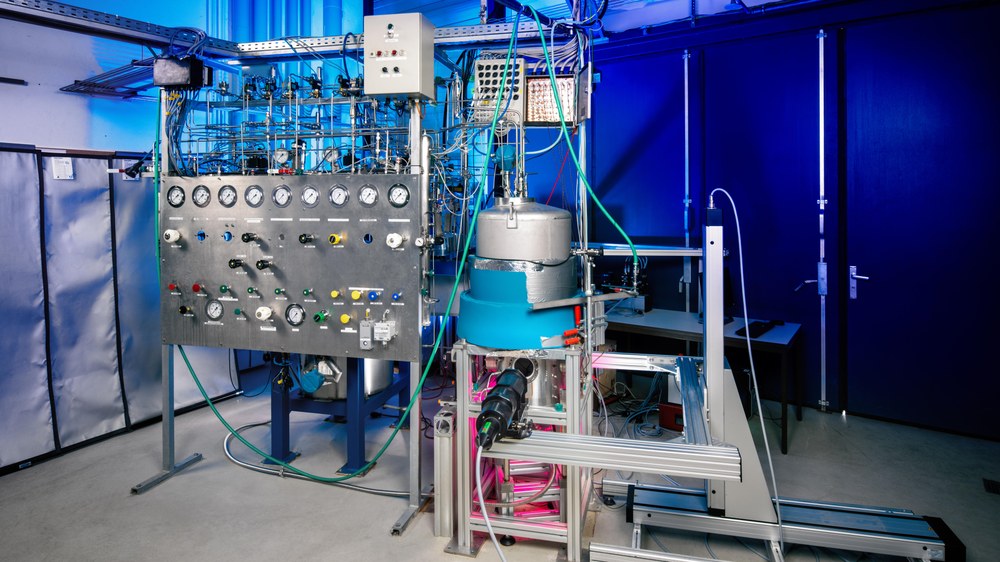

M3 test benches

The M3 test benches at the DLR-Institute of Space Propulsion in Lampoldshausen are used to investigate the treatment, injection, ignition and combustion of rocket fuels. This facility allows a large number of small-scale tests to be carried out under many different experimental conditions. The facility consists of three individual test benches – M3.1, M3.3 and M3.5 – each configured for different areas of research.

Conducting research with miniature combustion chambers

Experiments with rocket combustion chambers are carried out at the M3.1 test bench. The focus here is on investigating the transient processes involved in the injection of cryogenic fuels into a combustion chamber, and the ignition and combustion of the fuel mix. Among other investigations, it is possible to conduct basic research into the thermal load capacity of new structural materials for combustion chambers, or into new ignition methods, for example laser ignition. One major advantage of M3.1 is its highly modular hardware, while the overall M3 test facility enables multiple configurations to be tested quickly and flexibly.

Research into optimal rocket fuel injection

Both the M3.3 and M3.5 test benches are used to investigate transient two-phase flows. These are very important for the flow of cryogenic fuels through engine components – for example, valves, injectors and turbopumps – and the injection of fuels into a combustion chamber. The latter may take place in a vacuum, for instance if the combustion chamber of an upper stage engine is to be ignited in space. Here, too, the M3 test bench is distinguished by its highly modular setup and flexibility, so that there are almost no limits on the configurations that can be investigated.

The treatment, injection, ignition and combustion of rocket fuels takes place on a laboratory scale at the various small M3 test benches. The results of this laboratory research allow further tests on model combustion chambers to be carried out at other test facilities under conditions that are difficult to achieve on a laboratory scale.