DLR’s Flight Operations Facility is responsible for the deployment and utilisation of DLR’s fleet of highly-modified research aircraft.

Eurocopter BO 105

The five-seater Eurocopter BO 105 helicopter is based on a light, multi-purpose utility helicopter made by Messerschmitt-Bölkow Blohm GmbH (MBB), and has been significantly modified for its use as a universal research platform by the German Aerospace Center's (Deutsches Zentrum für Luft- und Raumfahrt; DLR) Braunschweig flight facility. The BO 105's service portfolio is very wide-ranging and is particularly suitable for use on diverse research missions. Amongst other things, it is used as a research platform for studying flight characteristics, low-noise approaches, thermal-imaging photography, pilot-assist systems and for flying with external loads.

Depending on the requirement, the BO 105 can be fitted with special equipment. This includes, for example, a nose boom for investigating inflow conditions, and with pressure sensors and strain gauges fitted on the main and tail rotor blades for measuring the forces and pressure conditions on the rotor blade.

It was the first helicopter in Germany to be equipped with a rigid rotor head and two turbines as standard. In addition, the BO 105 was the first helicopter whose rotor blades were made from glass-reinforced plastic. It is powered by two Rolls-Royce/Allison 250-C 20B engines.

Modifications

The following modifications differentiate the BO 105 helicopter from the standard BO 105:

- On-board computer for recording flight parameters.

- Nose boom for accurate measurement of inflow velocity and direction.

- Instrumented main and tail rotor for measuring forces and pressure conditions on the rotor blade.

- Hardpoints outside the cabin for payloads such as infrared cameras.

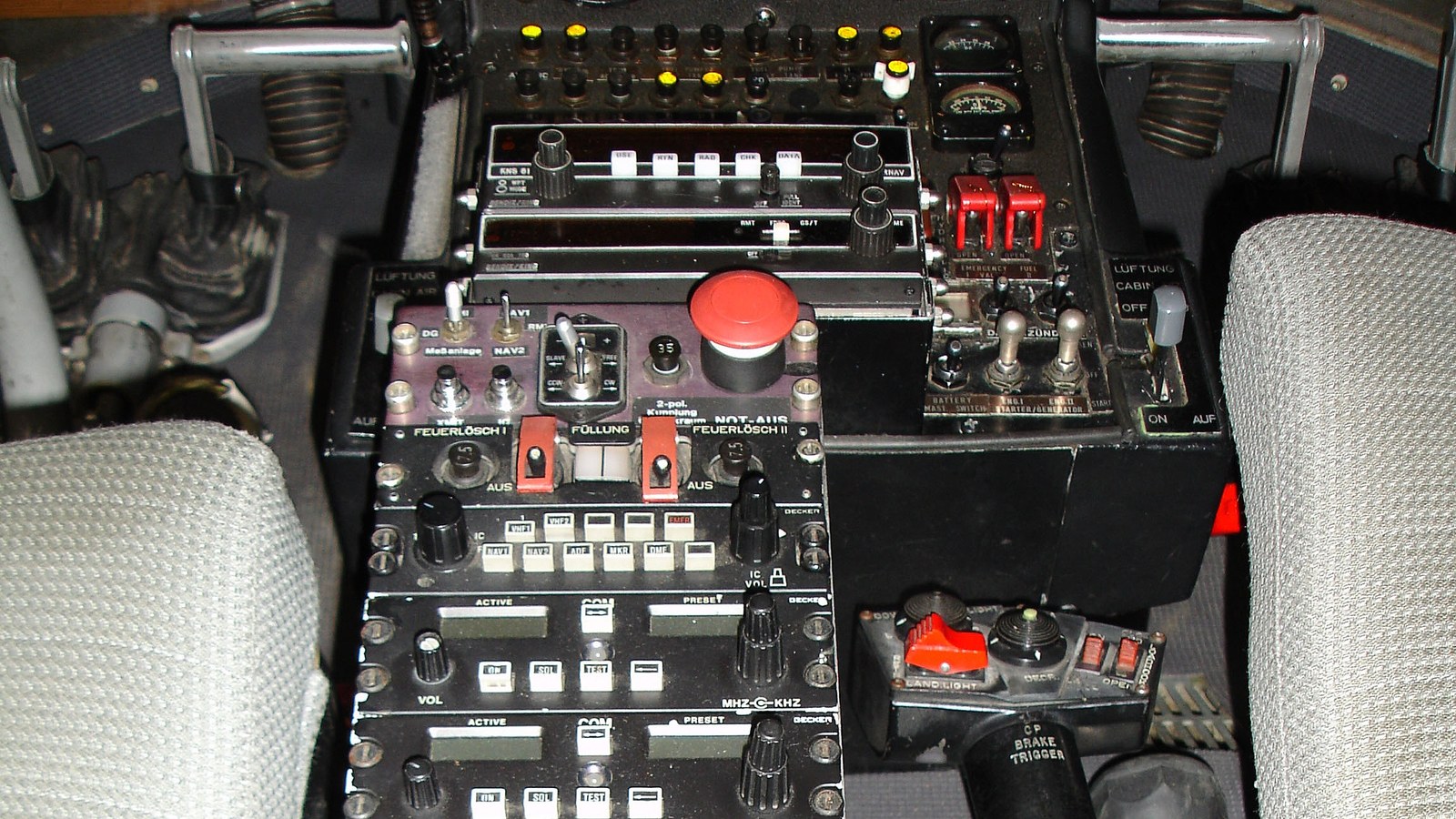

- IFR cockpit (Instrument Flight Rules) for flying in adverse weather conditions, the so-called Instrument Meteorological Conditions (IMC), which necessitate instrument flying.

- LASSIE system (Low Air Speed Sensing and Indicating Equipment). System for accurate measurement of air speed in the lower speed range.

- Flight Director concept for external loads. The system prevents load oscillations that often occur when transporting external loads on the helicopter.

Mission – research focus

The BO 105's fields of application are extremely varied; for example it is used for:

- Flight-characteristics studies

- Camera carrier for thermal imaging photography

- Investigation of low-noise approaches

- Development of pilot-assist systems

- Flights with external loads

'Flight Director' – Safe flying with external loads

Until now, pilots have normally faced a major challenge when transporting payloads, as two main problems occur when flying with external loads. Firstly, the pilot cannot see the load and secondly, the control strategy needed to reduce the swinging is unclear. If the pilot uses control inputs instinctively to try to reduce the swinging, the load movement is amplified even more in many cases. To offer pilots an aid for active damping of load oscillations and so increasing flight safety, the Flight Director concept for external loads was developed at DLR. The Flight Director is an instrument that provides the pilot with a command display for controlling the helicopter. In the application for damping load oscillations, the "Flight Director" uses an artificial horizon as a display. A command signal is superimposed on the normal input signal, resulting in optimal damping of the swinging.

Technology for improvement of flight characteristics

Using modern computer technology, DLR Flight Operations carries out research into improvement of flight characteristics. This includes calculating and measuring air flows on helicopters in flight. Using extensively modified main and tail rotor blades, DLR is able to measure the forces and pressure conditions on a rotor blade as it turns, and to record this data on the on-board computer for subsequent evaluation back on the ground.