Detecting supercooled water droplets under icing conditions

- In the SENS4ICE project, DLR and its partners are exploring icing caused by supercooled large droplets and its impact on flight characteristics.

- A combination of various technologies and sensors for the early detection of icing on aircraft is being investigated.

- Focus: Aeronautics

Icing on aircraft in flight is not related to the time of year, but rather the weather conditions. As part of the EU project SENS4ICE (SENSors and certifiable hybrid architectures for safer aviation in ICing Environment), the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is working with 18 international partners to conduct research into icing and its impact on flight characteristics. It is focusing on the specific phenomenon referred to as Supercooled Large Droplets (SLDs). Under very specific weather conditions, these supercooled droplets of water, with diameters in excess of 50 micrometres, can occur in the atmosphere and lead to icing on aircraft.

Larger aircraft are already equipped with effective de-icing systems for typical icing conditions. This prevents ice deposits from forming, particularly on wing leading edges and jet engine inlets. Such protective systems have been mandatory for the approval of commercial aircraft for decades. Under certain weather conditions, however, water droplets can occur in liquid form at sub-zero temperatures. For instance, this happens in inversion conditions, when water droplets from warmer layers of air fall through colder layers. The resulting large supercooled droplets only freeze if, for example, they meet the surface of an aircraft wing. In doing so, they can also lead to ice deposits behind the de-icing systems. "This SLD icing adversely affects the aerodynamic properties of the aircraft, so that the drag increases significantly, and the fuel consumption rises. In addition, it can have an adverse effect on the lift characteristics, and in very rare, extreme cases, this can cause the aircraft to stall," explains Project Coordinator Carsten Schwarz of the DLR Institute of Flight Systems. "For some years now, there have been additional certification requirements for these special icing conditions. Reliable sensors and methods that detect these SLD conditions are therefore an important component for aircraft designed to fly in icing conditions."

Warning of increased drag

In the SENS4ICE project, researchers are investigating a new approach to combining different detection techniques in order to enable early and reliable detection of SLD icing on aircraft. A monitoring algorithm is being developed for this purpose at the DLR Institute of Flight Systems in Braunschweig. This algorithm continuously analyses the flight characteristics of the aircraft. For example, if the drag changes significantly, this indicates possible icing on the aircraft. "At a certain point, the pilot would be able to recognise an advanced degree of icing because the increased drag requires more thrust. The benefit of the monitoring algorithm is that it enables even small changes to be detected, providing pilots with an early warning," says Schwarz.

An additional approach for detecting icing on aircraft as part of the SENS4ICE project is investigating results from various sensors, some of which have been newly developed. The researchers are examining a total of 10 different sensor technologies. Among other things, these are able to detect immediately whether any ice has formed on the surface of the aircraft. To this end, the DLR Institute of Composite Structures and Adaptive Systems is developing a special ultrasound sensor technology.

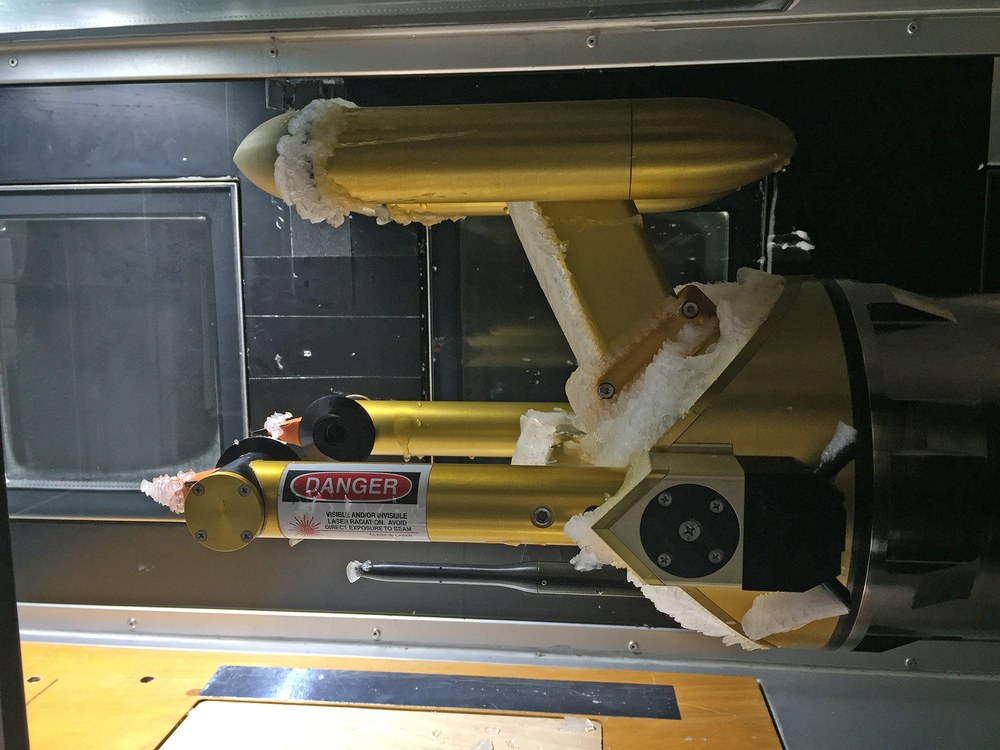

Other sensors, such as cloud particle probes, measure the atmospheric conditions, for example water content and droplet size. These use laser measurements to determine the number and size of droplets in the air. The DLR Institute of Atmospheric Physics is examining the cloud measurements and providing a reference for the new sensor technologies.

"We are talking about a hybrid solution here – the results from the indirect monitoring of the flight conditions and the direct sensors for observing the atmospheric conditions and ice formation are merged, making it possible for us to identify an icing issue on the aircraft more quickly and reliably," says Schwarz. The sensors best suited to the hybrid system will be tested in wind tunnels in Germany, the USA and Russia, and later in flight tests in North America and Europe.

The SENS4ICE project

DLR is leading the European Union SENS4ICE research project and working with 18 international research institutions and commercial organisations to investigate SLD icing. The project is overseen by an advisory board involving the European Aviation Safety Agency (EASA), the US Federal Aviation Administration (FAA) and other international bodies. The project is funded as part of the EU research framework programme Horizon 2020, under grant number 824253.