DLR retrofits 3D printer to produce medical protective equipment

The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) has successfully tested the conversion of its 3D printers. Where models for aerospace research are usually produced, medical protective equipment can be manufactured during the Coronavirus crisis.

The review was prompted by a request from the European Commission for assistance in the production of urgently needed medical equipment.

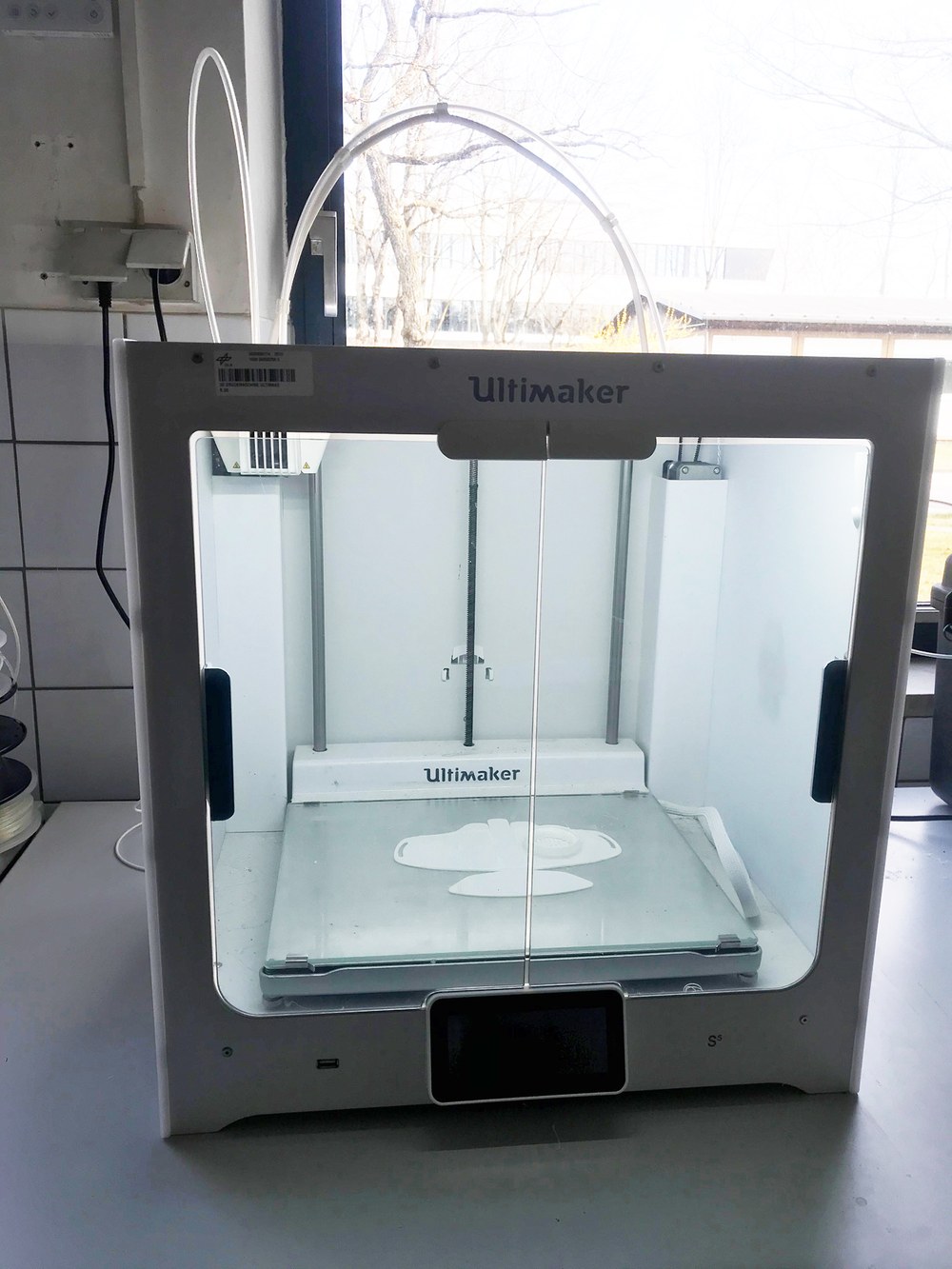

The request specifically addressed the production of protective masks and valves for respirators using 3D printing. Despite the absence of technical specifications (CAD data), DLR’s Systemhaus Technik and its other sources of engineering expertise have succeeded in conducting tests with components based on freely available templates and with plastics approved for use in the medical sector. The rubber-like materials selected for the masks ensure a good fit and high user comfort.

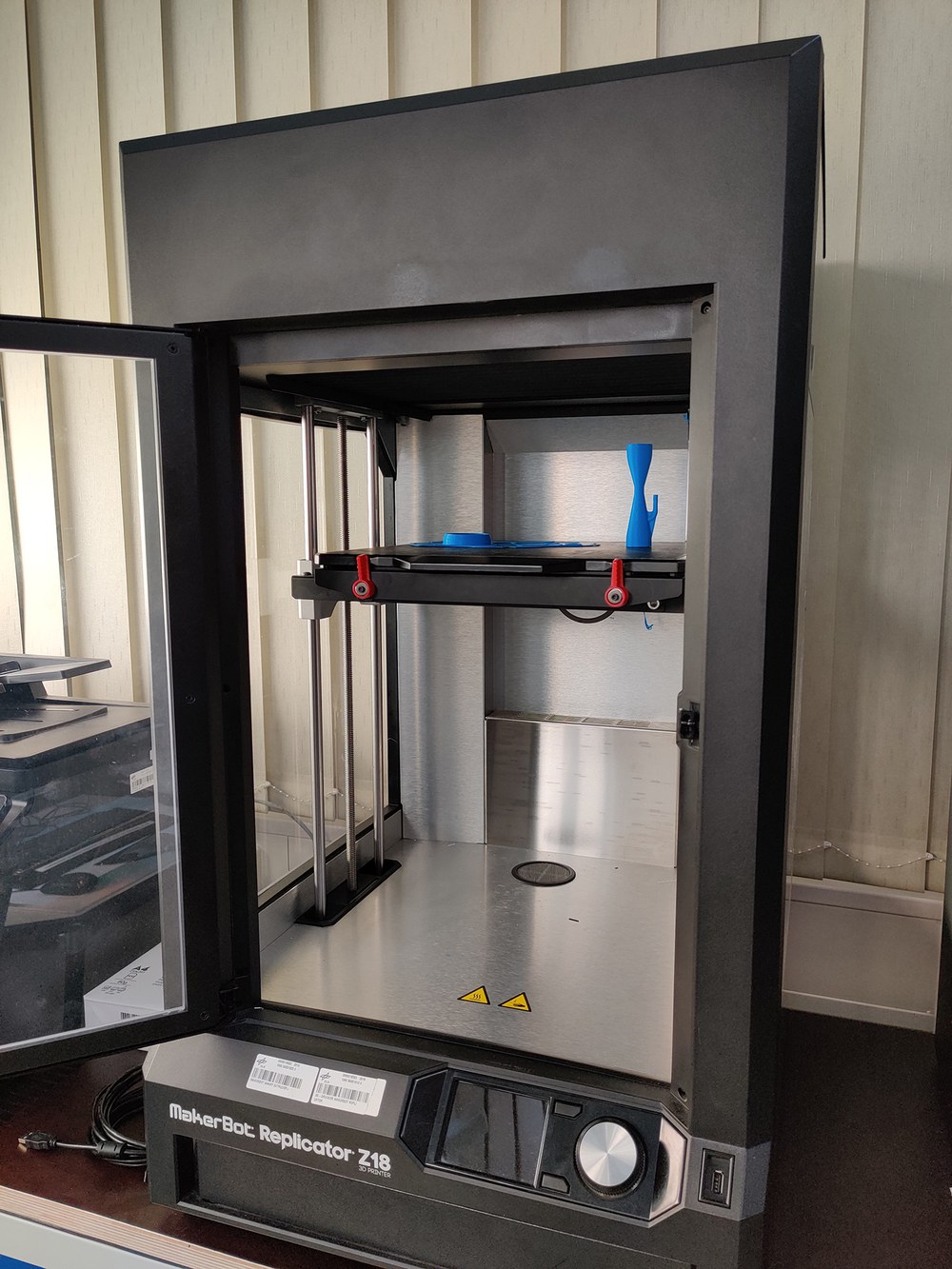

DLR’s 3D printer capabilities are currently being assessed. The performance varies, depending on the type of printer. For example, DLR has printers which, like an automatic hot glue gun, liquefy plastic granulate and print it in layers one on top of another. In others, liquid plastic is hardened using ultraviolet light.

The most powerful printers at DLR can produce up to 10 protective masks or 15 valves for ventilators per day. By networking institutes and facilities, it will be possible to produce larger quantities.

The certification and approval of the products produced by DLR for medical use is in progress. Systemhaus Technik is making its experience in converting 3D printers available to other scientific institutions.