DLR tests filter system to reduce virus load in enclosed spaces

- DLR tests ventilation concept for classrooms.

- Contract from OHB and HT Group.

- Focus: Coronavirus research

The German Aerospace Centre (Deutsches Zentrum für Luft- und Raumfahrt; DLR) in Göttingen has tested a ventilation concept with a filter system for classrooms, restaurants and cinemas. The test was commissioned by OHB System AG, the HT Group and Dastex and confirmed the effectiveness of the ventilation system in comparison with window ventilation.

In enclosed spaces, the risk of being infected by pathogens that are primarily transmitted via the human respiratory tract increases with the quantity of aerosols (source strength) and exposure time. The more aerosols, the greater the risk of infection, so the quantity of viruses must be reduced to counteract this effect. This can be achieved by diluting the indoor air with fresh air (through ventilation) or filtered air (with a room air filter). The OHB-HT concept is based on both displacement ventilation and the efficient filtration of potentially contaminated indoor air.

The ventilation concept under investigation for effective filtering of indoor air is a spin-off from the space and medical technology industries. ‘Next Generation Classroom’ is a retrofit kit for rooms that is easy to install and capable of effectively reducing the density of viruses (for example, Corona and influenza) – thus reducing transmission risk. Through a vertical ventilation system, air is introduced at floor level, extracted at the ceiling and, after being filtered, fed back in close to the floor. Heat generated by people in the room enhances the vertical air flow towards the extraction system. Exhaled air is fed into the filter system, so that virus-carrying aerosols cannot spread uncontrollably.

The new concept is the brainchild of Axel Müller, who specialises in cleanroom techniques in OHB’s Cleanliness Division. Cleanroom assembly ensures that satellite components are not subject to chemical, particulate or biological contamination, and that thermal influences do not interfere with high-precision measurements. This is achieved by optimising airflow to eliminate the disruptive influence of heat and sources of contamination.

Müller had precisely this in mind when he set out to design equipment to increase the safety of people in classrooms, doctor’s offices and other enclosed spaces: “The aim is to filter potentially virus-contaminated air quickly and to avoid uncontrolled mixing within the room,” he explains.

“As airflow researchers, we believe that this concept has huge potential and is better than window ventilation,” says Andreas Westhoff of the DLR Institute of Aerodynamics and Flow Technology in Göttingen, where the tests were carried out. Window ventilation is also referred to as horizontal ventilation – air enters the room from the side, swirls around and may come into contact with other people.

At the Institute, which draws upon decades of expertise in ventilation systems, especially in vehicles, Westhoff oversaw the first multi-day phase of the measurement campaign commissioned by OHB: “With the help of the tested prototype, investigation of the OHB-HT room ventilation concept has shown that a stable airflow can be achieved, from people straight to the extraction system, and the rising current generated by human body heat contributes to this effect. This reduces the uncontrolled spread of aerosols that are contaminated with viruses and bacteria from exhaled air. In addition, virus-contaminated air is effectively fed directly into the filter system.”

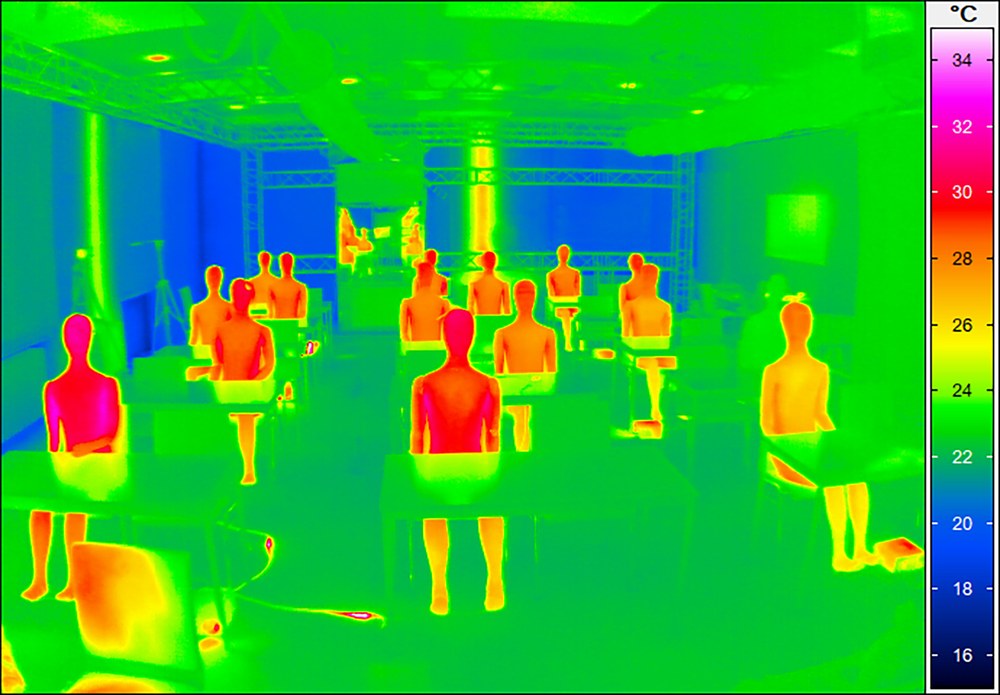

The measurements were conducted using heated human models – black mannequins wrapped in heating wire to simulate the heat output of a typical person in a seated position. “The heat given off by an individual creates a rising air current that has a significant impact on the flow in a room,” says Westhoff. In addition, a mannequin was equipped with a breathing simulator developed at DLR Göttingen.

Up to 15 mannequins were sat at tables in several scenarios: a classroom, a doctor’s waiting room, a catering area and a cinema. Smoke visualisation was added to make the airflow visible and verify the performance of the ventilation equipment. Carbon dioxide was also introduced into the room as a tracer gas, to simulate the spread of aerosols. With the help of carbon dioxide concentration measurements, the spread of virus-contaminated aerosols could be investigated.

Further testing will be conducted with the Next-Generation Classroom demonstrator in Göttingen over the coming weeks. Among other objectives, researchers aim to simulate the spread of human saliva particles. The consortium is also planning in-situ testing in a real school or restaurant.

How the OHB-HT concept works

A low-velocity ventilation system is installed to ingest potentially virus-contaminated air, filter it and return it to the room. This requires a fan, a HEPA (ultra-fine particle) filter unit and an air hose made of an aerospace-grade textile. Air conditioning can be added for temperature control in the summer months; LED strips mounted on the overhead air hoses could provide energy-efficient illumination.

HEPA filters and textile hoses are reusable; they can be exchanged at predefined intervals and reprocessed through professional cleaning or disinfection.

The OHB-HT concept is targeted not only at managing the current coronavirus pandemic, but also at improving indoor air quality in terms of pollen, bacteria, fungi and fine dust pollution.