Testing maintenance and ground processes for future aircraft generations

- The Hanseatic City of Hamburg is funding the construction of a hydrogen tank demonstrator.

- Over the next few years, aircraft maintenance processes and ground infrastructure will be researched.

- DLR is working together with Lufthansa Technik, ZAL and Hamburg Airport.

- Focus: Aeronautics, digitalisation, hydrogen, climate-friendly flight

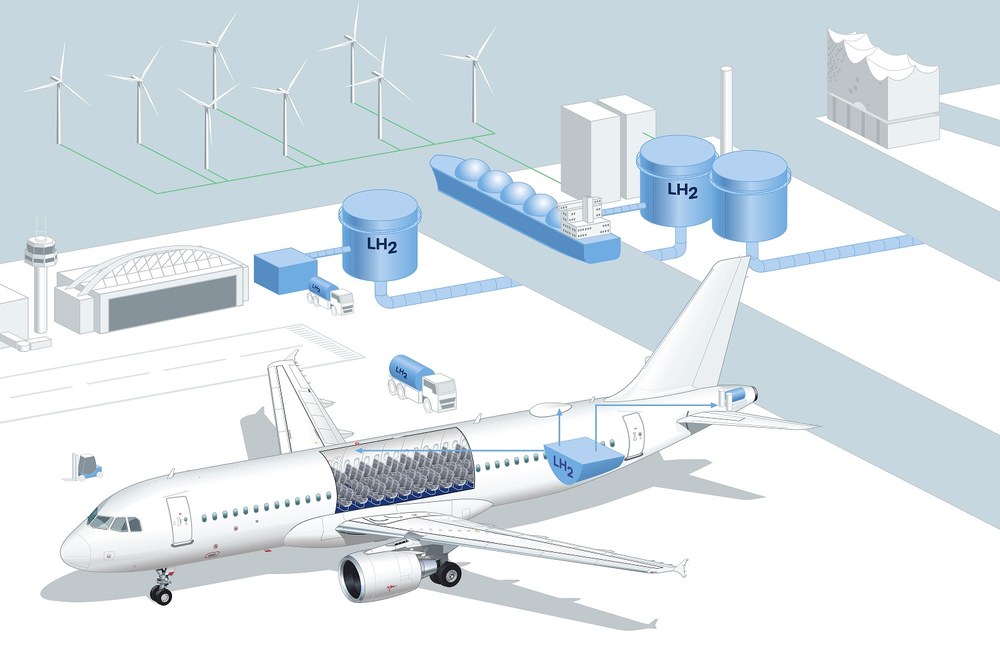

The air transport industry in Hamburg is preparing for flying with hydrogen. To this end, the starting signal has now been given for the establishment of a new development platform. Over the next two years and with funds provided by the City of Hamburg, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) together with Lufthansa Technik, the Center for Applied Aeronautical Research (ZAL) and Hamburg Airport will design and test extensive maintenance and ground processes for dealing with hydrogen technologies. For this purpose, an aircraft of the Airbus A320 family will be converted into a stationary laboratory at Lufthansa Technik's base in Hamburg.

Liquid hydrogen (LH2) is increasingly being envisaged in the development departments of large aircraft manufacturers as a sustainably producible fuel for future generations of commercial aircraft. In order to investigate the effects of the use of liquid hydrogen on maintenance and ground processes at an early stage, DLR, Lufthansa Technik, ZAL and Hamburg Airport are now combining their extensive practical and scientific expertise. The aim is to jointly develop a pioneering demonstrator, and to operate it from 2022.

As the world's third largest air transport location, the Free and Hanseatic City of Hamburg is funding the research project with the largest single item in its special programme to mitigate the economic impact of the coronavirus pandemic on the air transport industry.

"Hamburg is not only one of the three largest air transport locations in the world, last year the city also developed the clear vision of becoming a major hydrogen metropolis," explained Michael Westhagemann, Hamburg's Senator for Economics and Innovation. "I therefore see it as both a logical and gratifying step to combine these two core competences of Hamburg. The port, the energy sector, industry and the entire mobility sector are involved and are preparing for this groundbreaking technology. With this project, we are now also making an essential contribution to the transformation of air transport into a climate-neutral mobility solution of the future. The clear goal is to build up a hydrogen economy in Hamburg that will occupy a leading position internationally."

Planning of detailed development steps begins

In the first phase of the project, by the end of 2021 the partners aim to identify the most urgent fields of development for closer scientific consideration and, on this basis, to elaborate the concept for subsequent practical testing. The implementation of the concept will start at the beginning of 2022 and will involve the modification of a decommissioned Airbus A320 aircraft. It will be equipped with a liquid hydrogen infrastructure to be used as a fully functional field laboratory at Lufthansa Technik's base in Hamburg. In parallel, a virtual environment is being created at DLR that will be used to achieve a digital and highly accurate mapping of the defined development fields. The new development platform is to provide inspiration for the design process of the next generation of aircraft by means of parameterised and highly accurate virtual models.

Against this background, Lufthansa Technik will primarily contribute its extensive operational expertise in the maintenance and modification of commercial aircraft and can also incorporate the customer perspective through its close contact with airlines around the world. DLR will add its long-standing and cross-sectoral experience with hydrogen and focus on the development of the virtual environment. ZAL will also participate with its extensive expertise in the field of fuel cell technologies and its digital process mapping. As an associate project partner, Hamburg Airport will primarily contribute its experience from the operator's perspective, for example in defining requirements for the ground handling processing of future liquid-hydrogen-powered aircraft.

"There is no alternative to the transformation of our industry towards climate-neutral flight. With this project, we want to tackle this enormous technological challenge at an early stage – for the entire Maintenance, Repair and Overhaul (MRO) industry as well as for us. In this way, we are actively securing the future, because we are building up expertise today for the maintenance and ground processes of the day after tomorrow," explained Johannes Bussmann, Chief Executive Officer of Lufthansa Technik AG. "I am therefore pleased that we have succeeded in joining forces with strong partners in this project. And I am very grateful for the foresight of the city of Hamburg and its generous funding for this project."

"The aircraft of the future will be lighter, more efficient and fly with alternative propulsion concepts. Hydrogen will play an important role in this. We need to learn – promptly and in detail – what requirements real-world operations with hydrogen on the ground will place on aircraft and maintenance," said Markus Fischer, DLR Deputy Board Member Aeronautics. "In the project, we are using this data and experience to develop digital models for ground processes. These digital process twins can then be used directly in the design of future-oriented and yet practicable aircraft configurations."

"The development of a field laboratory and a digital twin are important components of Hamburg's Green Aviation Technology Roadmap. This were developed together with the members of the Hamburg Aviation Cluster last year to strengthen Hamburg's competence in research and development in a European context," said Roland Gerhards, Chief Executive Officer of ZAL GmbH. "We thank the city of Hamburg for its support in now jointly implementing this location strategy for the development of future liquid-hydrogen-powered aircraft."

Michael Eggenschwiler, Chief Executive Officer of Hamburg Airport, said: "Climate-friendly flying with hydrogen technology is only possible if the infrastructure on the ground also fits optimally. Close coordination is required here, and we as an airport are pleased to be able to contribute our expertise to this important project – from questions of storage and distribution to the refuelling process on the apron. At the airport, we also rely on hydrogen as the technology of the future for our ground transport. This project offers us the chance to identify and make the best possible use of synergy effects between gaseous hydrogen, such as that used for refuelling our baggage tractors, and liquid hydrogen for aircraft refuelling."

About Lufthansa Technik

With some 35 subsidiaries and affiliates, the Lufthansa Technik Group is one of the leading providers of aircraft technical services in the world. Certified internationally as a maintenance, manufacturing and design organisation, the company has a workforce of more than 22,000 employees. Lufthansa Technik's portfolio covers the entire range of services for commercial, VIP and special mission aircraft. This includes maintenance, repair, overhaul and modification of engines, components and landing gear, as well as the manufacture of innovative cabin products and digital fleet support.

About the ZAL Center of Applied Aeronautical Research

The ZAL Center of Applied Aeronautical Research in Hamburg is one of the most modern research facilities for civil aviation in the world. Over an area of 26,000 square metres, the research centre offers 600 personnel state-of-the-art facilities for joint research and development activities. Following the concept of 'Open Innovation', about 30 partner institutions from industry and science work here on the innovations of tomorrow. ZAL GmbH works in this unique environment with around 30 scientists and engineers. Both in partnership and on their own research projects, these aeronautics experts drive technological trends such as robotics, 3D printing, cabin networks and fuel cells.

About Hamburg Airport

Hamburg Airport is the fifth largest airport in Germany and is equipping itself with a modern infrastructure for all the challenges of air transport in the future. Around 15,000 employees work for almost 250 companies on the airport site (about 2000 in the Hamburg Airport Group alone). Shareholders of the partially privatised airport are the Free and Hanseatic City of Hamburg with 51 percent and AviAlliance GmbH with 49 percent. With the regions of Hamburg, Schleswig-Holstein and parts of Lower Saxony, Mecklenburg-Western Pomerania and Denmark, Hamburg Airport has a large catchment area and is the largest airport in northern Germany. In 2019, Hamburg Airport counted over 17 million passengers per year and around 140 direct destinations from 70 airlines.