Electric Space Propulsion Test Facility Göttingen – electric thrusters (STG-ET)

Electric space propulsion systems, which accelerate ions or plasmas to very high exhaust velocities, are becoming more common. The DLR Institute of Aerodynamics and Flow Technology in Göttingen is testing the thrust and fuel efficiency of these systems in its large-scale Electric Space Propulsion Test Facility (STG).

Very large vacuum chamber for thrusters

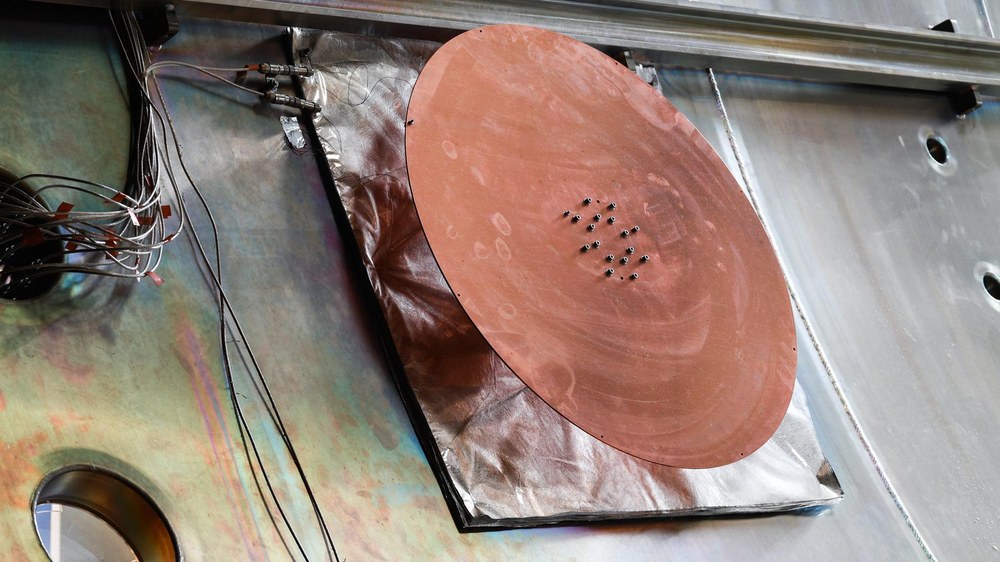

The testing of these kinds of innovative thrusters requires techniques that differ from those used with conventional chemical propulsion systems. For this reason, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) operates the STG-ET test facility, which is specially designed for electric thrusters. The core of this system is a vacuum chamber with a length of over 12 metres and a diameter of five metres. This makes the facility one of the largest of its kind in Europe.

The facility is used to test electric space propulsion systems. Depending on the test programme, it is possible to measure the thrust produced by a propulsion system or examine its plasma exhaust plume precisely using modern measuring technology. At the STG-ET facility, it is also possible to conduct the long-term tests that are also required for these types of thrusters.

In addition to investigations relating to the thrusters and their exhaust plumes, the facility enables analysis of the effects of the exhaust plumes on the surrounding environment and the spacecraft. Once the tests have been completed, the facility’s users and customers receive extensive data about the thrusters, allowing them to make improvements or achieve certification.