DLR´s Stuttgart site turns 60

Energy has always been an important matter in Stuttgart – and it goes far beyond the frugal energy-saving approach of the local Swabians. Engineers, hobbyists and ingenious inventors have long been channelling their creative energy into countless innovations, particularly regarding mobility on land, on water and in the air. Founded in 1954, the Research Institute of Jet Propulsion Physics had even greater ambitions – outer space. In 1961, it became the heart of DLR´s Stuttgart site.

Over the following six decades, DLR Stuttgart has become home to a host of new institutes focusing on energy and transport research. Today, the Institute’s research topics include safe and carbon-neutral air transport, sustainable energy production using renewable sources, innovative vehicle concepts for the transport of tomorrow, as well as safe and efficient spaceflight.

Already in the 1960s, the research conducted at DLR’s Stuttgart site was interdisciplinary. At the time, work at the institutes primarily focused on propulsion technologies, designing re-usable spacecraft and developing energy converters and electric propulsion systems. However, the technologies, knowledge and competencies that arose from aerospace research had to address challenges on Earth – namely in the area of energy supply. The DLR researchers began with the development of new storage and conversion systems for solar and wind energy. One of DLR’s predecessor organisations, the German Test and Research Institute for Aviation and Space Flight (Deutsche Forschungs- und Versuchsanstalt für Luft- und Raumfahrt; DFVLR), was the first major institution to carry out systematic research into renewable energy and the use of hydrogen. In 1977, the International Energy Agency commissioned DLR with the construction of two solar power plants in Almería, Spain, to demonstrate the technical feasibility of this environment-friendly method of gener ating electricity.

New materials and high-performance components

In the 1970s, innovative materials and construction methods began to replace conventional techniques. Newly developed composite materials, for example, could be used to construct ultra-light rotor blades for wind turbines. Fibre-reinforced ceramic components proved more resilient to high temperatures than metals. New manu facturing methods helped DLR laboratories to develop these high-tech materials for use in gas turbines, engines or the heat shields used to protect spacecraft as they re-enter Earth’s atmosphere. A Stuttgart-based sports car manufacturer even went on to use similar ceramics in their brake discs.

Lasers in materials processing and standoff detection

During the 1980s, an entirely different innovation began to establish itself in conventional Swabian mechanical engineering. Lasers were developed for cutting and welding. Microprocessor-controlled laser material processing machines could now manufacture components with a precision almost impossible to achieve using conventional methods. Over the years, DLR Stuttgart has developed numerous prototypes of innovative gas and solid-state lasers with output powers of many kilowatts. Thousands of industrial laser systems today make use of the operating principles developed here. Even the possibility of using laser power to launch microsatellites into space has been tested. Today, researchers at the site are working on laser and optical systems for defence and security, standoff detection of hazardous substances, drone identification, laser-based flight instruments and the detection of space debris.

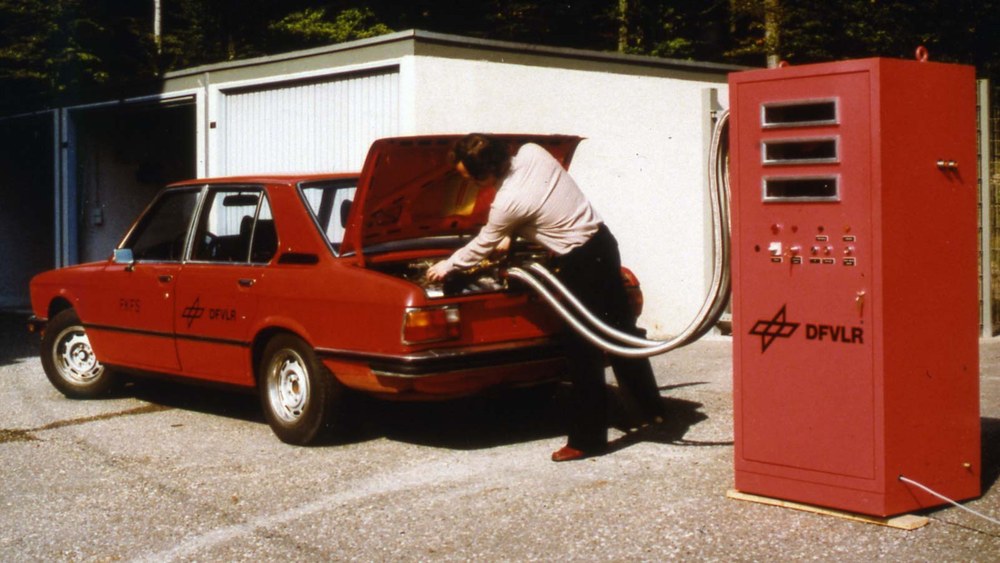

Hydrogen for energy and transport

The oil crisis of the 1970s was one of the primary drivers of the first hydrogen-powered car, built at DLR Stuttgart in 1978. Specialists used the vehicle to investigate how this alternative fuel could be reliably stored. There was even a hydrogen fuelling station on site. In 1985, DLR researchers demonstrated how hydrogen could be used to generate electricity on a large scale. They built two photovoltaic electrolysis plants – one in Stuttgart and another in Riyadh, Saudi Arabia, with a power of several hundred kilowatts.

This project marked the beginning of fuel cell research in Stuttgart. During the 1990s, the site carried out pioneering work on the development of membrane fuel cells with several kilowatts of electrical output power. With new types of electrode manufactured by plasma spraying, they achieved 20 percent higher efficiency. The DLR researchers also had other applications in sight, ranging from energy converters for cogeneration plants to high-efficiency vehicle and aircraft engines. A milestone was reached with the maiden flight of the Antares DLR-H2, the world’s first passenger aircraft powered solely by fuel cells and a predecessor of the modern four-seater Hy4.

A new millennium – a new age for transport and energy

In 2002, a new research focus was established at DLR Stuttgart: the design of innovative road and railway vehicle concepts to facilitate sustainable transport systems powered by renewable energy. Here, researchers developed the first car powered by a fuel cell. This vehicle was the predecessor of DLR’s latest road transport concepts: the Urban Modular Vehicle (UMV) People Mover, and the ultra-light commuter Safe Light Regional Vehicle (SLRV). With the U-Shift project, researchers developed a futuristic vehicle concept with a basic chassis and interchangeable capsules for transporting people or goods. The electrically powered driveboard is able to autonomously carry various capsule types round the clock.

The Next Generation Train project addresses the future of rail transport: the development of safe, light and robust trains running on high-efficiency electrical, battery or fuel cell power at the speeds at which aircraft take off. Many of these DLR technologies can already be seen in everyday life, including Germany’s first hydrogen-powered passenger train.

To ensure a safe and controllable supply of renewable energy, DLR Stuttgart is conducting interdisciplinary research into industrially viable key technologies for heat storage, batteries, green hydrogen and synthetic fuels. Examples are the Test Facility for Thermal Energy Storage in Molten Salt (TESIS) and the research platform for decentralised energy sources (TPDE), which is based on micro gas turbines. With these, DLR researchers are trying to find out how to achieve sustainable power generation nationwide. They are also conducting flights to test environment-friendly biofuels. In view of the rising global demand for energy, DLR researchers are devising concepts to generate power and heat as efficiently as possible. They are even combining various technologies such as high-temperature fuel cells and gas turbines in new hybrid power plants. Researchers at the DLR site in Stuttgart are also working on new technologies and materials for solar thermal power plants to lower the cost of electricity generated using solar power. One example is the CentRec heat receiver concept which is the key element of a pilot solar tower plant providing a factory with climate-neutral process heat.

Reaching even greater heights in 2021

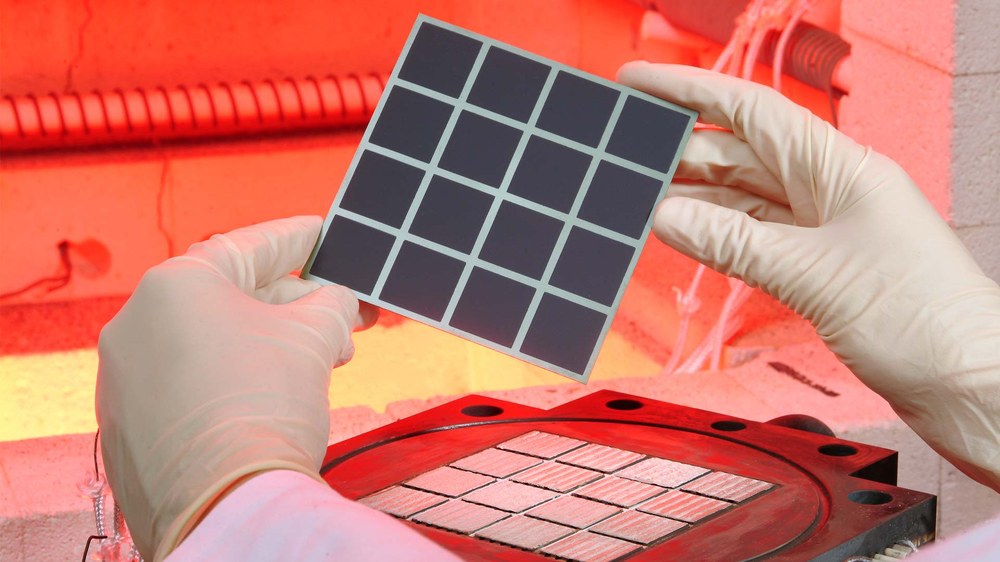

The Integrated Digital Research Platform for Affordable Satellites (IRAS) project is investigating innovative satellite construction methods. 3D printing, green propulsion technologies, novel structural forms and electronic circuitry and manufacturing processes will allow satellites to be manufactured far more sustainably and economically in the future.

And finally, even DLR must not forget the traditional Swabian Kehr woche in Stuttgart. Rather than cleaning the house, however, DLR researchers are using lasers and optical telescopes to detect space debris and determine how best to remove it from orbit. They can determine the position of objects to within just a few metres. This will allow active satellites to carry out effective avoidance manoeuvres and prevent in-orbit collisions.

Today 750 staff members work at six institutes at the DLR site in Stutt gart. Even trainees go in at the deep end as far as research is concerned, working in systems electronics, precision engineering, office manage ment or dual study programmes in mechanical engineering, electrical engineering or information technology. They are also the best in their field, regularly winning top prizes and positions at state and national level – in other words, they are brimming with energy.