DLR at the Hannover Messe – Taking energy further

Batteries and fuel cells for the vehicles of tomorrow, solar thermal power plants, heat storage and smart rotor blades for wind turbines – there are plenty of opportunities to make the energy supply of the future clean and sustainable. At the Hannover Messe, as part of a broader exhibition by the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), current energy research projects will be presented for the first time on Booth G31 in Hall 27 between 13 and 17 April 2015. The projects show the spectrum of energy research at DLR – from basic research to specific industrial applications. In addition, DLR is represented on the Hydrogen Fuel Cells stand (Hall 27) and on the German Federal Ministry for Economic Affairs and Energy (Bundesministerium für Wirtschaft und Energie; BMWi) stand (Hall 2).

Efficiency and flexibility through energy storage

Waste heat from industrial processes can be collected with the aid of thermal storage and reintegrated into the industrial process or converted into electricity. In solar power plants, thermal storage allows electricity to be generated at night. In the electric vehicle of the future, thermal storage will play a role for air conditioning and heat management. The DLR Institute of Engineering Thermodynamics will be exhibiting innovative conventional heat storage, latent heat storage and thermochemical heat storage at the trade fair. Together with industry, researchers are developing new storage concepts for various applications – from fundamentals through to market maturity.

Fuel cells, electrolysis and a hydrogen-powered delivery bicycle

Fuel cells generate electricity without moving parts – noiselessly – and without exhaust gases. DLR conducts research on fundamental areas of cell and stack development, as well as on application-oriented tasks such as the integration of fuel cells into decentralised stationary power plants or small aircraft. The DLR Institute of Engineering Thermodynamics will display a model of a real solid oxide fuel cell stack and an interactive presentation of DLR projects in the fields of high-temperature fuel cell research and electrolysis. The DLR Institute of Vehicle Concepts, together with DLR Technology Marketing, will present a fuel-cell powered cargo bicycle. Loaded and in hilly terrain, the bicycle has an average range of about 200 kilometres. By replacing the hydrogen cartridge, the bicycle can be refuelled quickly and easily.

Receiver and storage in one

At the Hannover Messe, DLR solar researchers will present a novel radiation receiver with which electricity production in solar thermal tower power plants is more cost effective and efficient. In a tower power plant, mirrors reflect sunlight onto a receiver at the top of the tower, where it is converted into heat. In the new concept, ceramic particles are irradiated in a rotating receiver, where they absorb the Sun’s rays and convert it into heat. At the same time, the ceramic particles, which can be heated up to 1000 degrees Celsius, also act as a storage material.

Battery research and a simulated drive in an electric car

DLR will be showing its work on fundamental techniques in battery research. Scientists from the DLR Institute of Engineering Thermodynamics are improving the characteristics of lithium-ion batteries and the next generation of batteries with the help of computer-aided electrochemistry and numerical simulations. In addition, the scientists are carrying out application-related research – among other things with the interactive Lithium-ion Battery Tester (LiBaT). Trade fair visitors can simulate driving an electric car by taking a trip in a virtual city and thereby generating a load profile that is transmitted directly to a real battery.

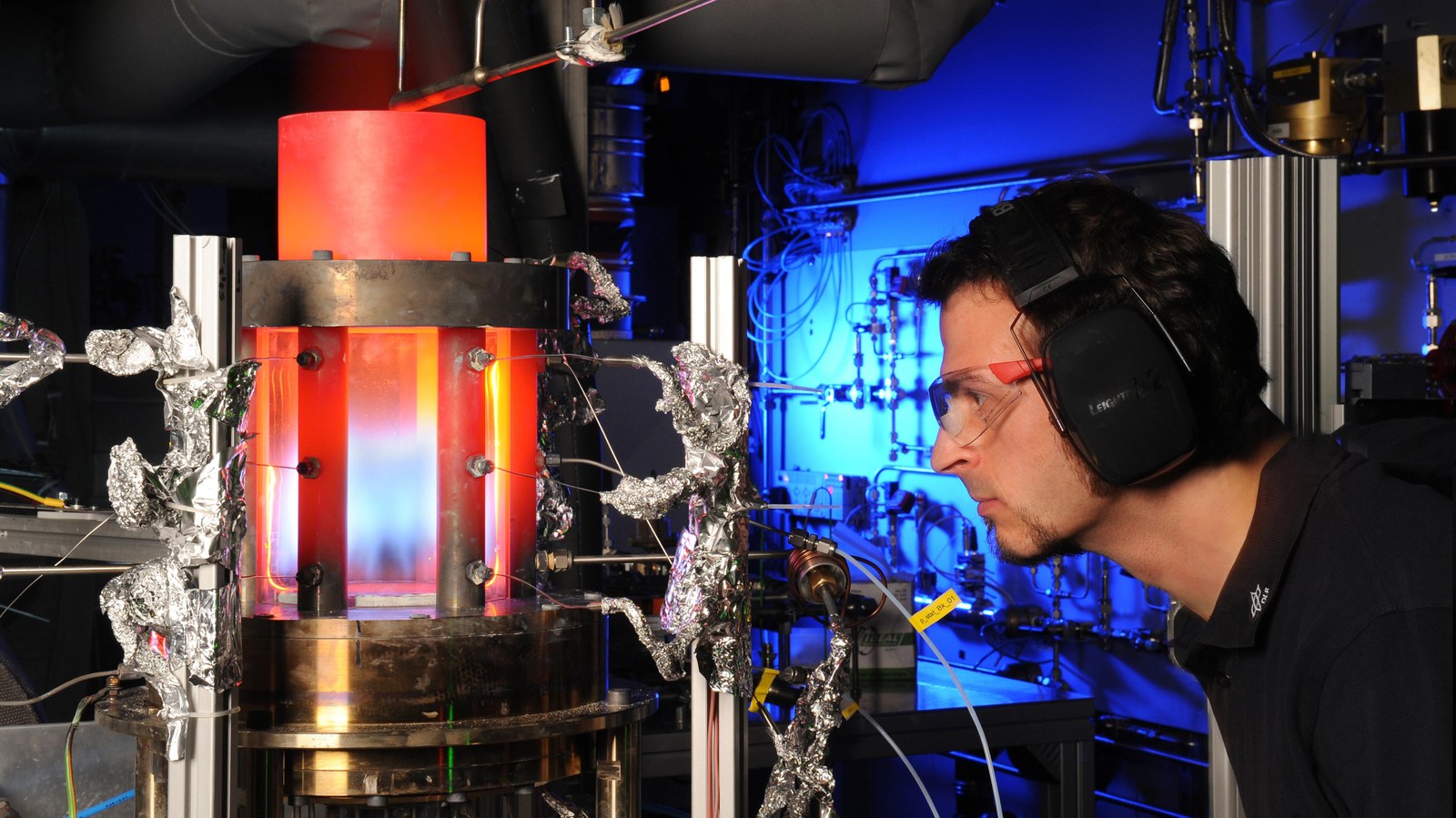

A combustion chamber and new radial compressor

Messe visitors can take a look inside the DLR transparent combustion chamber to see the combustion processes inside gas turbines. Researchers at the DLR Institute of Combustion Technology are using laser sensing in the combustion chamber to investigate how the efficiency and pollutant emissions from power plants and aircraft turbines can be improved further. The DLR Institute of Propulsion Technology will be presenting a novel radial compressor. Radial compressors are used particularly in gas turbines. DLR researchers have designed a radial compressor using advanced simulation and optimisation methods that include new possibilities for Computer Numerical Control (CNC) manufacturing. During tests of the high-performance radial compressor, researchers were able to measure an efficiency increase of 1.5 percent. DLR will also introduce the FLameless OXidation (FLOX®) combustor, which can burn different fuels very stably and efficiently.

Thermoelectric generator – flying with hand heat

Heat flows in aircraft turbines, internal combustion engines and industrial processes are often lost as unused waste heat. Thermoelectric generators (TEG) use this waste heat and convert it into electrical energy. Thus, processes that generate heat as a by-product become more energy-efficient and the environment is protected. The DLR Institute of Materials Research exhibit uses the electrical energy generated by two such generators to control a model helicopter. The heat from a visitor’s hand is enough to act as an energy source for controlling a helicopter’s altitude. In direct comparison, two people can measure the energy produced by their hands against one another and thus experience thermoelectric generators up close.

Smart rotor blades for wind energy research

Smart rotor blades, exact simulation methods and fast real-time modelling for wind turbines are the focus of DLR wind energy research. The goals are higher yields from wind turbines, more full-load hours and lower environmental impacts. DLR researchers are also working on reducing the noise resulting from wind turbines through innovative structures and manufacturing methods. DLR will be demonstrating its wind energy innovations at the Hannover Messe on a 1:2 scale section of a wind turbine rotor blade.

DLR Technology Marketing

DLR Technology Marketing provides the interface between research and industry. It is responsible for the cross-industry transfer of DLR technologies and is the point of contact for innovation-friendly companies of all sizes. Together with DLR institutes and with the earliest possible involvement of industrial partners, DLR Technology Marketing turns research results into application-enabling technologies, investigates markets and trends, develops innovative ideas, ensures competitive advantages through intellectual property rights, makes agreements relating to the marketing of DLR technologies and supports DLR spin-offs. Therefore, DLR Technology Marketing welcomes all industry representatives to explore the possibilities for cooperation with DLR.

Start your mission at DLR – advice on entry and career opportunities

IAt DLR, researchers are pioneering innovations for the world of tomorrow; students, career starters and people with professional experience can work on interdisciplinary projects in basic and applied research. DLR Personnel Marketing will give advice at the Hannover Messe on Entry and career opportunities.