HYDROSOL_Plant: Hydrogen from sunlight

- DLR scientists start operating new test facility for hydrogen production with solar energy

- The performance of the facility has been improved thanks to redevelopment of the materials and structure of the reactor

- Focus: renewable energy, hydrogen

On 28 November 2017, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), together with international project partners, presented what is currently the largest solar-chemical installation for the production of hydrogen. In the HYDROSOL_Plant project, scientists and companies have jointly further developed the process of direct hydrogen production using solar radiation. By redeveloping both the materials used and the structure of the reactor, the facility can now provide a power of 750 kilowatts. This is a significant improvement over the previous development stage of this facility, which had a power output of approximately 100 kilowatts. At Plataforma Solar de Almería (PSA) of the Spanish research centre CIEMAT (Spain), scientists will in the coming months produce hydrogen in test operations and demonstrations in southern Spain, and investigate the suitability of materials.

Hydrogen – an important energy source for the power and transport sector

Hydrogen has the potential to increase the proportion of renewable energies used, particularly in the transport and heating sectors. This energy source can, for example, be used directly in vehicles with fuel-cell drives. In addition, it is a component in the production of synthetic fuels such as methane, methanol, petrol and kerosene. Hydrogen generated using renewable energies can thus significantly reduce carbon dioxide emissions in the transport and heating sectors. Karsten Lemmer, DLR Executive Board Member responsible for Energy and Transport emphasised: “In the transport sector, hydrogen drives can make a significant contribution towards climate protection. The HYDROSOL_Plant research project is thus a significant step on the road to efficient production of hydrogen using solar energy."

This international project, coordinated by the Greek Aerosol and Particle Technology Laboratory (CERTH-CPERI-APTL), is a collaboration between DLR, the Spanish Centro de Investigaciones Energéticas Medioambientales y Tecnológicas (CIEMAT), the Dutch company HyGear and the Greek energy supply company Hellenic Petroleum. The DLR Institute of Solar Research is predominantly responsible for the development of the solar reactor, the layout of the facility and the measuring and control technology. The project is funded by the European Technology Initiative on Fuel Cells and Hydrogen Joint Undertaking (Fuel Cells and Hydrogen Joint Undertaking, FCH 2 JU).

Efficient water splitting using sunlight

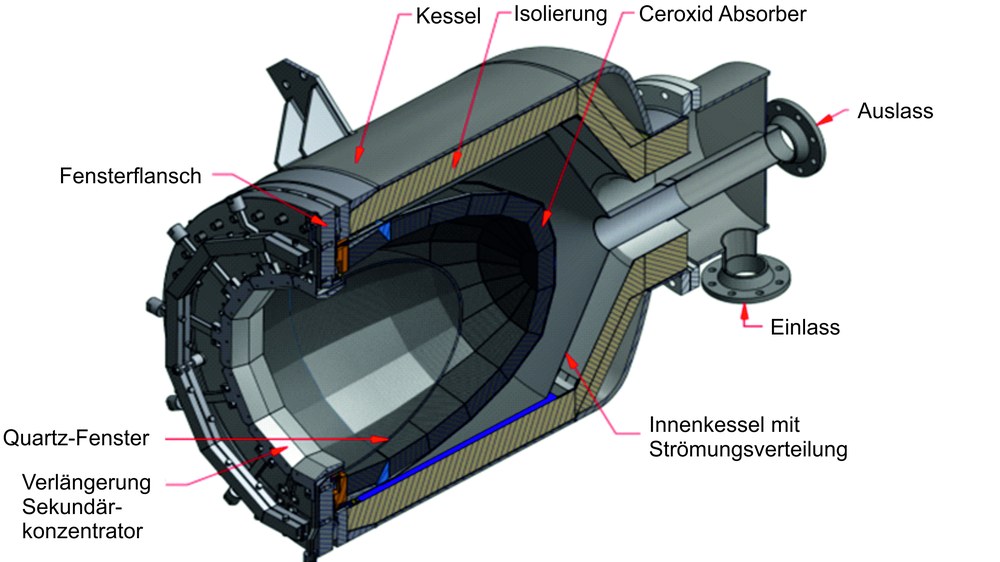

Hydrogen is produced directly via a thermo-chemical redox reaction using the thermal energy of the Sun. A set of mirrors focuses the sunlight onto a single point that is heated up to very high temperatures. With this heat, water can be split into hydrogen and oxygen. In the first part of the procedure, the Sun heats redox materials, such as nickel ferrite or cerium oxide, in the interior of the reactor to 1400 degrees Celsius. At these temperatures, the metal oxide is chemically reduced, that is oxygen is released and transported out of the reactor. The actual water splitting occurs in the second step, which takes place at 800 to 1000 degrees Celsius. Here, the researchers let water vapour flow through the reactor. The previously reduced material is reoxidised. As the oxygen is now bound into a metal oxide, it remains in the reactor, whilst the hydrogen is free to be transported out of the reactor. Once the material is completely reoxidised, it is regenerated through the first step of the procedure and the cycle starts again.

Higher efficiency, greater durability

Building on earlier research projects, the scientists have significantly advanced both the structure of the reaction chamber as well as the materials. The solar radiation is secondarily focused using a cone with a coating of reflecting material, which increases the efficiency of the process as less heat can escape. Newly-developed ceramic foams hold promise for a higher hydrogen yield and greater durability. The researchers expect that these will produce around three kilograms of hydrogen per week in test mode. Martin Roeb, Project Manager at the DLR Institute of Solar Research explains: “With the HYDROSOL_Plant, we have for the first time designed a plant that reproduces the entire process, from generation, through the separation of high-purity hydrogen, to its storage. Although our work is still in the research phase, we can already generate one kilogram of hydrogen per week, which is a significant amount. An efficient fuel-cell vehicle can travel well over 100 kilometres on one kilogram of hydrogen."

Industrial application possible in a decade

Hydrogen is one of the most important basic chemical elements. At this moment it is mainly used in the production of fertilisers and to desulfurise crude oil. In Japan there are already 200,000 fuel cell systems are already being used in buildings. The aim is to also use hydrogen in large gas power plants to produce energy and thus replace fossil and nuclear power plants. The use of hydrogen in industrial applications, such as steel production, could also lead to significant reductions in carbon dioxide emissions. Researchers reckon that it will be at least a few years before the procedure is ready for the market and for commercial applications. “The first applications could act as a stand-alone solution, for instance in areas where there is no connection to the electricity network. In those cases, a production of 10 kilograms per week may already be worthwhile. Depending on how fast development progresses, in 10 years time it will be possible to use this procedure for the industrial generation of hydrogen,” Roeb is convinced.

The general idea behind the HYDROSOL project and the demonstration of its feasibility have already received numerous scientific awards, including the European Union’s Descartes Prize in 2007 and the Eco Tech Award at the World Exposition in Tokyo in 2005.