Test stand professionals

Hydrogen offers enormous potential for climate-friendly aviation. Unlike kerosene, hydrogen combustion produces only water and heat … at least in theory. However, this fuel also has its challenges. For hydrogen to remain liquid, it must be kept cooled to minus 253 degrees Celsius. In addition, hydrogen burns differently to kerosene. Researchers at the DLR Institute of Propulsion Technology in Cologne are investigating exactly how this potential new aircraft fuel can be burned safely and with low emissions. To do this, they are using modern high-pressure combustion chamber test stands in combination with state-of-the-art laser-optical measurement technologies. Bertram Janus, Acting Co-Director of the Institute and Head of the Combustor Department, and Christian Willert, Head of the Engine Measurement Systems Department, talk about why this technology is in such demand.

Which classes of aircraft will be powered by hydrogen in future?

Bertram Janus: That still needs to be determined. Our understanding of what the different branches of technology can achieve is constantly growing. There are different approaches to achieving climate-friendly passenger aircraft. For short-haul routes, expectations are more focused on 'electric flight'. In this context, research is also being conducted into hybrid approaches that use hydrogen as an energy source.

However, in this case, the gas is not burned in an engine, but converted into electrical power in fuel cells; this then drives the propellers. We, on the other hand, are researching the direct combustion of hydrogen in conventional engines designed for medium-haul aircraft. This is where the greatest potential for combustion-based hydrogen operation is currently thought to be. With that in mind, we are cooperating with various engine manufacturers who are developing demonstrators. The current tests at DLR are focused on an engine class designed for business jets.

Airbus wants to develop the world's first hydrogen-powered commercial aircraft by 2035 …

Bertram Janus: That is right. This aircraft manufacturer is initially planning a technology demonstration on the ground, and later also in the air. They intend to install a modified engine on an Airbus A380 to show that hydrogen propulsion is possible in principle. Studies on the climate impact will be carried out at the same time. This will be a major milestone on the way towards hydrogen-powered aircraft. The major engine manufacturers with whom we are cooperating in various EU-funded projects are supporting this approach. The preliminary combustion tests are being carried out at DLR in Cologne.

Hydrogen engines are expected to start being used in civilian air transport by 2035. What obstacles need to be overcome before then?

Bertram Janus: The interim goal is to have engine demonstrators on the ground. We are conducting research on our test stands, which allow us to observe the combustion process from the outside, through a window. We are learning to better understand the behaviour of the burner and the combustion chamber and will be able to eliminate any fundamental technical uncertainties. As soon as there is sufficient confidence in the burner, more application-oriented experiments will follow on larger, more complex test stands. Here, entire annular combustion chambers can be examined under conditions that correspond to a real engine. After further successful tests, the engine manufacturer will install the combustor in an engine.

We are learning to better understand the behaviour of the burner and the combustion chamber and will be able eliminate any fundamental technical uncertainties. As soon as there is sufficient confidence in the burner, more application-oriented experiments will follow on larger, more complex test stands.

Why are the tests being carried out by DLR, rather than by industry? What can DLR do that the private sector cannot?

Bertram Janus: Facilities such as our High-pressure Combustion Chamber Test Stand 1 (HBK1) provide industry with exceptional infrastructure. For instance, pressure-resistant quartz windows allow unique views into the otherwise closed combustion chamber. This enables us to characterise the combustion behaviour and determine the flow within the chamber. We use specially developed laser-optical measurement methods for this.

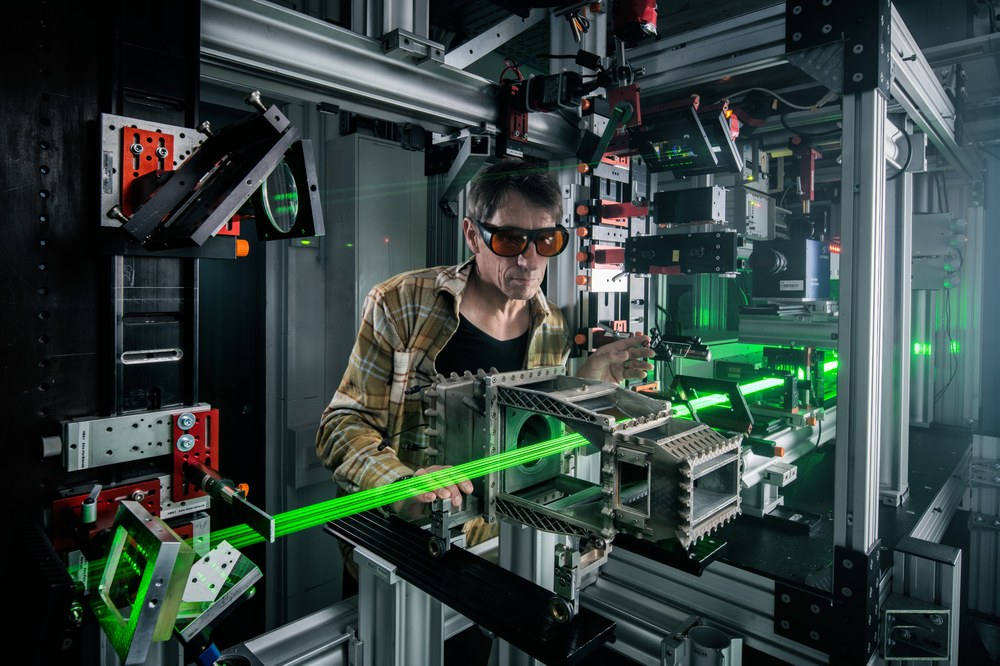

Christian Willert: We use a range of measurement techniques in the experiments. These complete the picture of the combustion process and allows us to check and improve on simulations that our colleagues from the Numerical Methods Department have carried out beforehand. The optical measurements allow us to record the reaction and heat release zones without influencing the combustion chamber flow. We can also use flow field measurements to track the movement of the air/hydrogen mixture and the reaction products through the combustion chamber.

Bertram Janus: Our researchers use HBK1 to examine technological developments at an early stage. HBK5 is DLR's largest combustion test stand. Entire annular combustion chambers can be examined here, up to technological readiness levels of five or six. DLR in Cologne has created numerous test stands and these are continuously developed and adapted to address new requirements. In addition, we have unique infrastructure for the air, kerosene and special fuels that supply our facilities, depending on the research subject. Our excellent hydrogen infrastructure has been a particularly valuable asset for a number of years.

How are hydrogen tests actually carried out in the windowed high-pressure combustion chamber?

Bertram Janus: You can imagine it like 'cutting out' a segment of the annular combustion chamber of an aircraft engine. The windowed chamber is usually operated with individual burners under realistic conditions – a high air preheating temperature and operating pressures up to 25 bar. This is what makes this test stand unique. The burner is then tested under various operating conditions, such as idling on the ground or taxiing towards the runway or into a parking position, as well as when taking off and during the flight phase. We have a measurement system that analyses the composition of the exhaust gas and can look into the combustion chamber to measure the flows there. We also use measurement methods that map chemical processes in the combustion chamber. We are keen to improve the fuel injection process, so as to produce the lowest possible level of pollutants.

Christian Willert: Our imaging method uses lasers to create light sheets which transect the combustion chamber. This makes individual planes visible within the studied volume. In a sense, you could liken this to computed tomography, where the brain is shown in two-dimensional slices using X-rays. In our case, the cameras that film through the viewing window in the combustion chamber reveal these planes.

Our imaging method uses lasers to create light sheets which transect the combustion chamber. This makes individual planes visible within the studied volume.

Where do you see potential for optimisation?

Bertram Janus: The deeper the insights we gain into the flow, the better the starting points we have for optimising the processes in the combustion chamber. This will allow us to avoid temperature spikes, for example. Very high temperatures sometimes arise for a short time when the air and fuel combine, which promotes the formation of harmful nitrogen oxides. For hydrogen tests, we use a burner that we designed ourselves and that allows us to influence phenomena and processes. In this way, we can determine whether the technical idea behind it is borne out in reality.

Christian Willert: There is further potential in the rear part of the combustion chamber, at the outlet duct, where the hot gas flow transfers thermal energy to the engine structure. Our lasers allow us to visualise things that the eye cannot see. For example, we work a lot with ultraviolet light to excite radicals – hydroxyls, molecularly combined oxygen and hydrogen – with the resulting fluorescence used to determine concentrations and temperatures. Having an optimal design for the temperature distribution is also extremely important at this point in order to prevent damage to the turbine and to achieve the longest possible service life.

If you burn 100 percent hydrogen, do you really only get water and heat as 'waste products'?

Christian Willert: The only thing that comes out of the turbine is water vapour. Because there is nitrogen in the air, nitrogen oxides can also be produced; these must be avoided or at least minimised. Contact with the cold ambient air causes contrails to form, just as is the case with conventional jet fuels.

Are there synergies between the Institute of Propulsion Technology and other DLR institutes when it comes to hydrogen combustion tests?

Christian Willert: Very much so. We work together with the Institute of Combustion Technology in Stuttgart on matters relating to combustion engineering and combustion diagnostics. We are also in close contact with our colleagues at the Institute of Aerodynamics and Flow Technology in Göttingen in relation to measurement methods for high flow velocities. Due to the use of hydrogen in rocket engines, there is also overlap with the space researchers at Lampoldshausen in terms of developing optical measurement technologies.

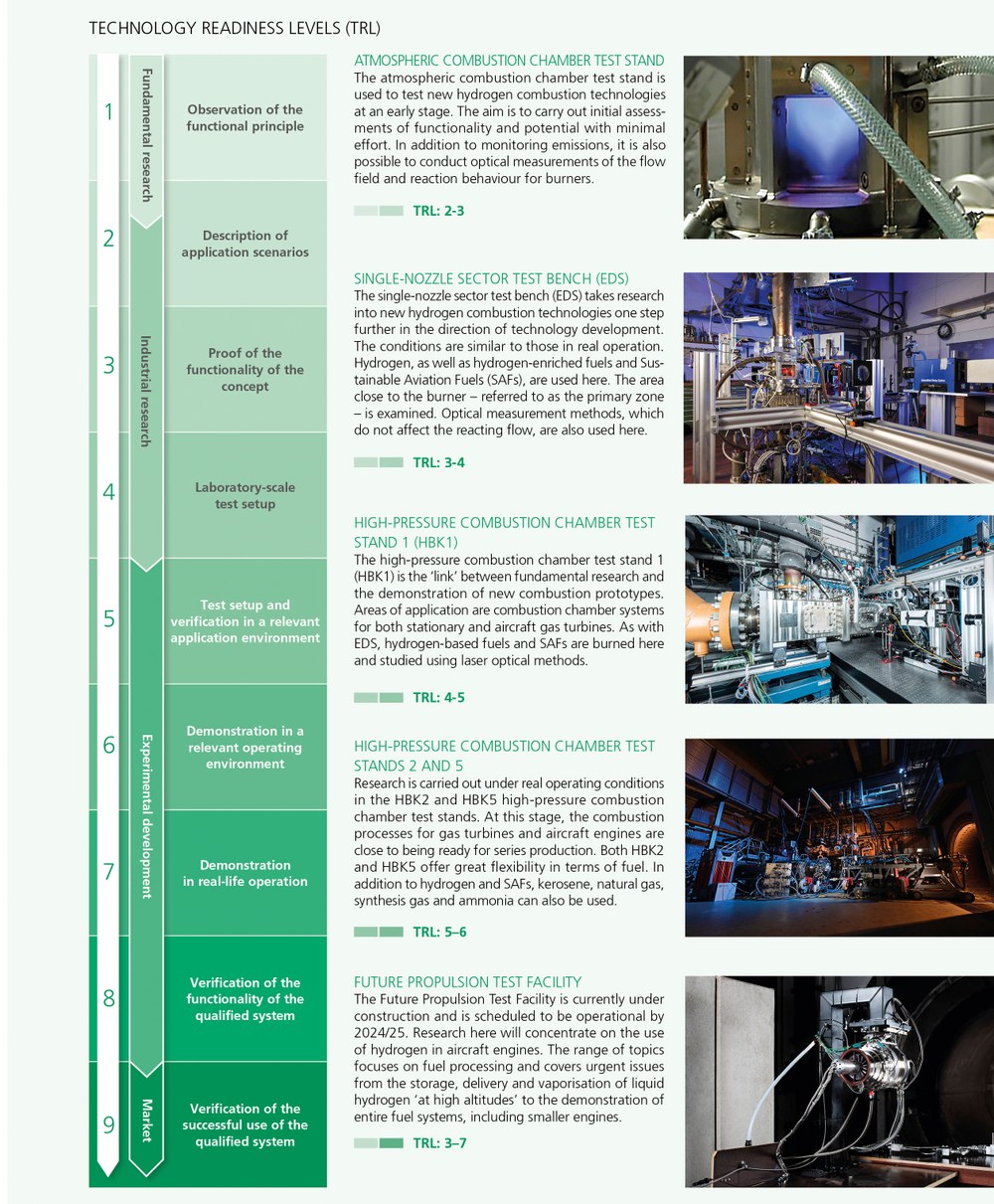

Hydrogen test facilities at the DLR Institute of Propulsion Technology in Cologne

The interview was conducted by Michael Müller, editor in the DLR Corporate Communications Department. An article from the DLRmagazine 174.