Quality assurance and management

Systemhaus Technik is certified to ISO 9001, an internationally recognised standard for Quality Management Systems (QMSs). This standard supports organisations in optimising processes and increasing customer satisfaction, setting out the requirements for effective quality management and integrating the principles of quality management and quality assurance into a structured framework.

Key principles

ISO 9001 is based on several key principles that guide the implementation of an effective QMS:

Customer focus

The standard highlights the importance of understanding and meeting customer needs and expectations. To increase customer satisfaction, Systemhaus Technik employs tools such as SWOT analyses, complaints procedures, stakeholder analyses and regular strategic customer dialogues. The quality management system is routinely reviewed for effectiveness through internal and external audits.

Leadership

Managers play a pivotal role in fostering an environment that encourages engagement and motivation. They are responsible for setting quality objectives and ensuring the availability of necessary resources.

Engagement of people

The involvement of all staff is essential. Every team member is expected to actively participate in the continuous improvement process and undergo training to promote a culture of quality.

Process approach

ISO 9001 requires the identification and management of processes, promoting greater efficiency and higher quality outcomes.

Evidence-based decision making

Decisions must be grounded in the analysis of data and facts. The standard mandates the systematic collection and evaluation of information to drive continuous improvement.

Relationship management

Maintaining strong relationships with suppliers and partners is critical to ensuring quality throughout the value chain.

Quality assurance

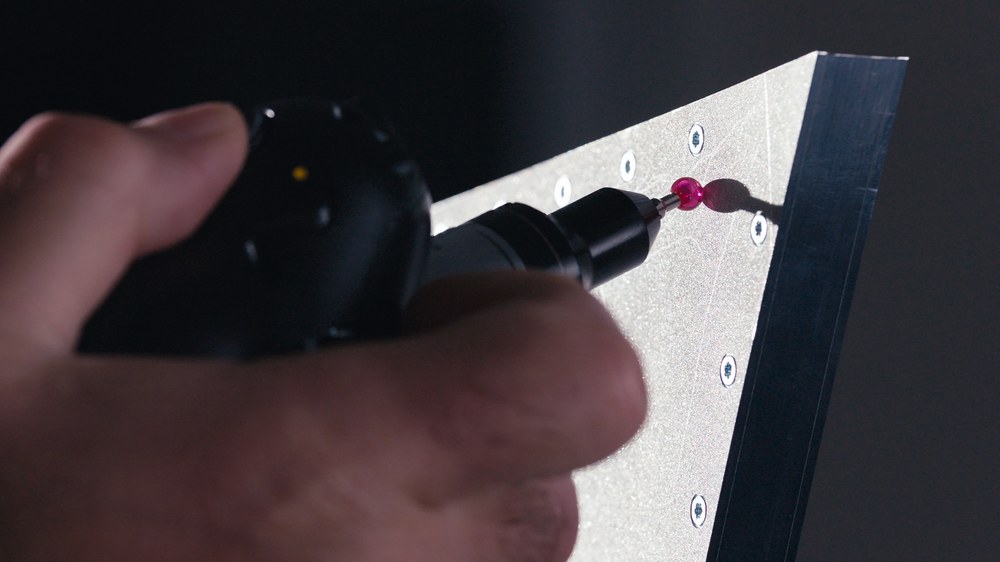

Quality assurance is a core element of ISO 9001, comprising specific measures to ensure that products and services meet the specified quality standards. Systemhaus Technik employs precise measuring techniques for components, with all measuring and testing equipment regularly calibrated by external service providers to guarantee accuracy.

Geometric dimensioning and tolerancing

When creating product specifications in Systemhaus Technik, geometric tolerances (form, orientation, location and run-out) are meticulously considered. These tolerance specifications are adhered to across design, manufacturing and quality assurance processes. Their proper application can reduce manufacturing costs compared to overly tight dimensional tolerances that neglect geometric factors.

Audits

Regular audits form a key part of the quality management system. Both internal and external audits are conducted to ensure compliance with ISO 9001 requirements and evaluate the effectiveness of processes. These audits identify opportunities for improvement and support Systemhaus Technik in continually raising its standards and maintaining the quality of its products and services.