Step 2: Longitudinal stiffening

Step 2: Longitudinal stiffening

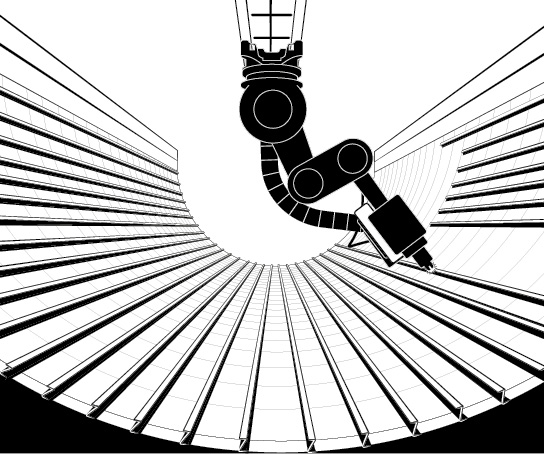

Forty-four longitudinal stringers are welded onto the aircraft skin. The process used for this is called robot-based continuous ultrasonic welding. In a world first, thermoplastic films called energy directors are placed between the two parts that are to be welded together. A robot stimulates the components at 20 kilohertz. They begin to rub against each other, generating temperatures of around 380 degrees Celsius within a fraction of a second and welding the components together. The process is significantly faster than the drilling and riveting commonly used in the aviation industry.

Credit: DLR (CC BY-NC-ND 3.0)