Micro gas turbines

The energy system of the future will be based on energy from renewable sources. This has many advantages but one major disadvantage - the electricity yield will fluctuate significantly over a day and throughout the year. The department is further developing micro gas turbine technology for precisely these applications.

These fluctuations become more noticeable the larger the distribution grid and the more significant the proportion of renewable energies are. To compensate for this fluctuation, highly flexible and low-emission decentralised power plants based on gas turbines will make a decisive contribution to the sustainable and grid-compatible supply of electricity and heat.

Advantages of micro gas turbines

In the department, we are working on further developing micro gas turbine technology, which can be used in such decentralised power plants. At present, combined heat and power plants based on reciprocating engines or gas engines are predominantly utilised for decentralised electricity and heat generation because their electrical efficiency is still somewhat higher than that of micro gas turbines. However, micro gas turbine technology offers considerable advantages in terms of fuel flexibility and significantly lower pollutant emissions. A wider range of liquid and gaseous fuels can be used in microturbines. Further advantages of the microturbine are the considerably longer maintenance intervals, the low specific operating and maintenance costs, the simpler design and the low noise emissions. Due to the higher exhaust gas temperatures, gas turbines are more suitable for generating process heat and cooling.

Combining micro gas turbines with high-temperature thermal storage

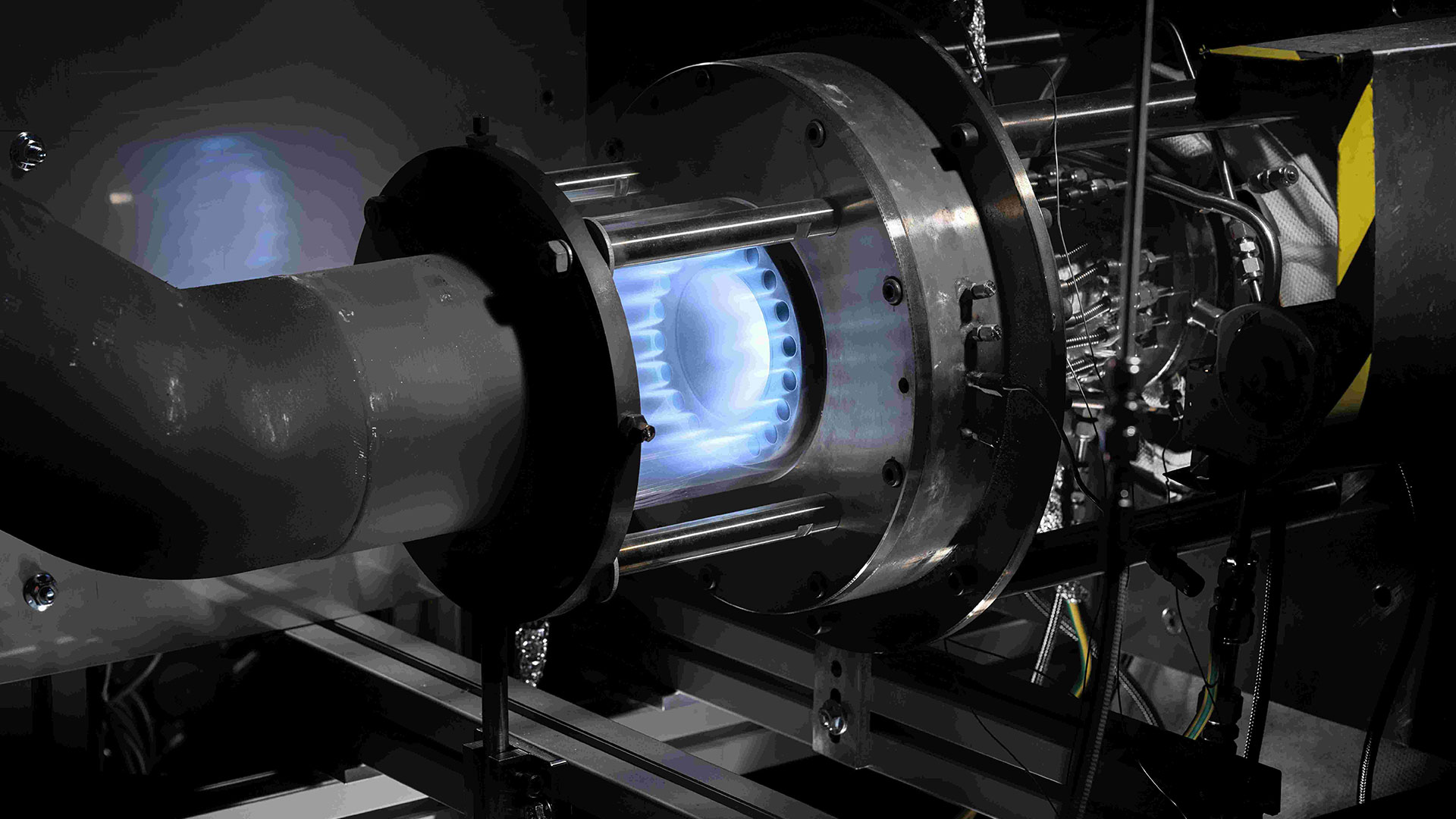

We want to improve the systems available on the market and are developing new components to increase electrical efficiency and reduce costs. We develop our own control concepts and optimise the operating mode of the systems, taking into account different application scenarios and concerning service life. To open up further application areas for micro gas turbine technology, we investigate innovative gas turbine cycles and their combination with other technologies (e.g., high-temperature thermal energy storage, heat pumps, and fuel cells). We use our simulation tools for the design of these developments. For experimental investigations, we have several laboratories and micro gas turbine test benches at our disposal where we can analyse the new developments on real systems.

Using our expertise in gas turbine combustion, we develop fuel-flexible and low-emission combustion chambers in the department to make micro gas turbines even more robust and flexible. To this end, we rely on jet-stabilised combustion concepts that can be scaled particularly well and are, therefore, suitable for a wide range of performance classes. We have a number of modern laboratories and test benches at our disposal for development, where we analyse and optimise burner systems under atmospheric conditions, for example.

The department's work focuses on the following areas in detail:

- Combustion systems for micro gas turbines

- Micro gas turbine-based power plant concepts

- Innovative gas turbine cycles and hybrid concepts

- Numerical cycle and plant simulation for micro gas turbine-based power plants

Based on our experience and technical equipment, we offer the following research services

- Technology assessment of micro gas turbine concepts

- Optimisation / new development of combustion chamber systems