Development of new combustion chambers

Even under the changed framework conditions of the energy transition, combustion remains an important pillar of global and national energy generation.

Fuel and load flexibility combined with low emissions are taking centre stage, while efficiency increases remain relevant against the backdrop of high throughputs worldwide. The Institute develops innovative combustion systems based on decades of experience and supports industrial development work at manufacturers of gas turbines of various sizes with its work. The focus here is on the concept of jet-stabilised burner systems (link to research topic), which is characterised by exceptional fuel flexibility and low emission values. This concept is already being used in the first industrial plants and gas turbine applications.

Jet-stabilised burner concepts for gas turbine applications have been investigated, developed and further optimised at the Institute for around 20 years. The Institute has tested these concepts for operating conditions in large gas turbines and small recuperated gas turbines in its test rigs. In addition, the Institute has conducted fundamental research on flame stabilisation, mixing and injector interaction for many fuels, including hydrogen, at atmospheric and high pressure conditions. These experiments have shown that the concept of jet-stabilised combustion can be operated with low emissions and without the risk of flashback, especially with hydrogen over a wide parameter range. Other fuels investigated include natural gas, methane-hydrogen mixtures, synthesis gases and various liquid fuels, whereby the latter pose a challenge in terms of their small size. The development work benefits from the use of optical and laser-based measurement technology to visualise the combustion state and the support provided by combustion simulation.

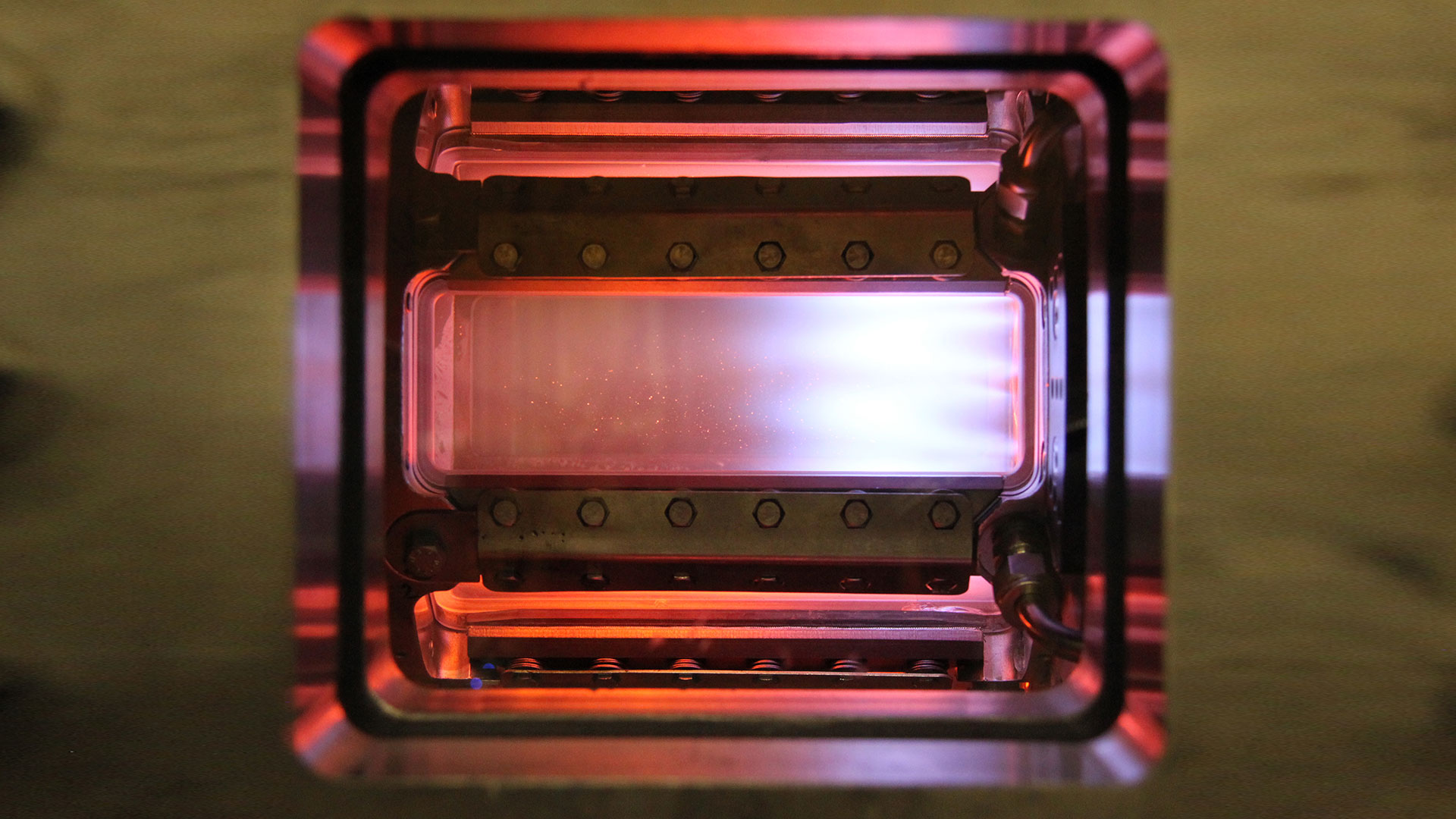

In addition to pioneering and supporting work for manufacturers of large gas turbines and industrial gas turbines, the institute has also successfully developed and demonstrated the application of the system for micro gas turbines in the 3 kW to 400 kW electrical power range. In 2022, the institute developed a highly scaled prototype for a nominal fuel output of around 1000 kW (F1000s) using only CFD and FEA simulations. This system can use natural gas, biogas and synthesis gas to operate a recuperated gas turbine with combustion chamber inlet temperatures of up to 700 °C and a pressure ratio of around 5. For the development of combustion chambers and a better understanding of combustion processes, the institute has developed its CFD code THETA (link), which enables a detailed numerical simulation of complex combustion systems using detailed chemical reaction mechanisms (link) optimised for the respective application.

Abbildung 2 zeigt einen Prototyp der F1000s-Brennkammer. Das Design basiert auf der F400s-Brennkammer, die kürzlich erfolgreich mit 100 % Wasserstoff in einer Turbec T100 Gasturbine getestet wurde. Damit konnte das Institut nachweisen, dass ein Betrieb mit 100 % Wasserstoff in den selbst-entwickelten Brennern für Mikrogasturbinen möglich ist. Ein erster Langzeittest im Wasserstoff-Technikum am DLR-Standort Lampoldshausen läuft zurzeit.

We not only work with the concept of jet-stabilised combustion chambers, but also support industrial companies and research institutes with high-pressure tests using optical diagnostics, CFD simulation and the development of combustion kinetic mechanisms in the development of other burner concepts. The optimisation of combustion processes for the best available fuel and the required flexibility of plant utilisation will remain an important task for the foreseeable future.