Frequently Asked Questions about gas turbines and energy transition

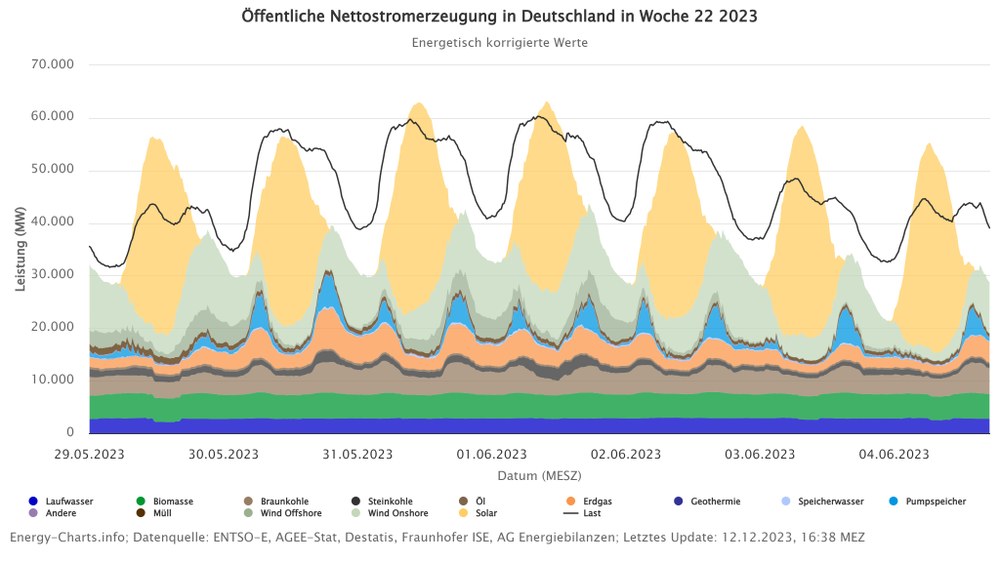

Combustion technologies will remain indispensable in the energy system of the future for a long time to come - for example, as a back-up solution for the dark days of the year when neither wind nor sun provide energy. We provide answers to the most important questions in our field of research.

www.energy-charts.info

www.energy-charts.info

Combustion will remain indispensable for sustainable mobility and energy supply in the future

The energy system of the future will rely entirely on energy generation from renewable sources such as wind, solar and hydropower, geothermal energy and renewable raw materials. Germany aims to produce energy largely climate-neutral by 2045 at the latest. By 2050, these sources are expected to account for around 60 per cent of gross final energy consumption and 80 per cent of gross electricity consumption. Technical combustion processes will still play a role even then - wherever electrification is difficult to achieve and whenever the sun is not shining or there is not enough wind. Our aim is to further develop combustion processes for operation with sustainable chemical energy sources in such a way that they release virtually no pollutants and are even more efficient. Gas turbine and combustion research contributes to adapting and retrofitting existing power plants and the development of new gas-fired power plants.

Where is combustion used in electricity production?

Relying entirely on energy generation from wind and sun will come with a downside - the energy cannot be produced in line with demand. The energy supply fluctuates both over the course of a day and over the course of a year. In addition, the power is also unevenly distributed over space. Two things are needed to compensate for these spatial and temporal differences: controllable output and good storage facilities. This is where gas turbine power plants come into play. Gas turbines are characterised by great load and fuel flexibility. They can be ramped up and ramped down comparatively quickly. These properties will become all the more important in the future as the share of renewables increases and more coal-fired power plants are shut down..

Gas turbines will therefore continue to be in demand to supply electricity and heat using non-fossil fuels. However, in future they will be operated in a way to which they still need to be adapted: Up to now, turbines have primarily been designed to operate efficiently and economically at full load. In future, they will often only operate at partial load and with new and changing fuels such as hydrogen and hydrogen mixtures - and they will have to be re-optimised for this highly variable operation in order to burn as low in pollutants as possible. According to estimates, Germany will need between 30 and over 100 GW of load-flexible or controllable power generation. Up to now, coal-fired power stations have also been used for this purpose. Replacing these coal-fired power plants with gas turbines, which are then gradually converted to non-fossil energy sources such as hydrogen, is essential for the energy transition. We are developing combustion chambers specifically for operation in a resilient and sustainable energy system.

How clean is the electricity production of gas turbines in comparison with other sources?

Gas turbines are often mentioned in the same breath as coal-fired power stations. However, gas turbines are significantly less polluting: they emit only half as much CO2 as coal-fired power stations, and nitrogen and carbon monoxide emissions from gas turbines are now just a few parts per million (ppm). Coal-fired power stations, on the other hand, generally require exhaust gas aftertreatment. In 2022, coal-fired power plants accounted for 17.3 per cent of energy production across Europe - just under a fifth. In Germany, coal-fired power plants were even the most important energy source for electricity production in 2022, according to the Federal Statistical Office. A third (33.3%) of the electricity generated in Germany and fed into the grid came from coal-fired power plants - in 2021, this figure was 30.2 per cent, meaning the share is actually increasing again. Quickly replacing coal-fired power plants with power plants with fuel-flexible gas turbines would be one of the most effective steps towards a rapid defossilisation of the energy system. As a rule, these could then be converted to sustainable fuels such as hydrogen at a manageable cost (i.e. without further investment in infrastructure).

Where is reconversion used?

In future, gas turbines and decentralised, modular power plants in the small and medium power class are to be operated with up to 100 percent hydrogen and possibly other synthetic fuels. To this end, existing plants will be converted and new, optimised plants developed. With its power plant strategy, the BMWK is focussing on hydrogen hybrid power plants and hydrogen-based electricity storage systems, among other things. The combination of the two makes it possible to use renewable electricity to generate hydrogen regionally, store it and convert it back into electricity in gas-fired power plants when required. However, gas turbines with a connection to a hydrogen infrastructure are also to be operated with renewable hydrogen. This applies both to hydrogen sprinter power plants, which are to generate electricity with hydrogen from the outset, and to gas-fired power plants, which will initially be operated with natural gas and then converted to hydrogen by 2035.

What role does combustion play in heat production?

Providing heat for industry and private households in line with demand without resorting to fossil fuels will be a challenge - this sector will undergo an even greater transformation than the electricity sector. However, gas-fired power plants can also make a decisive contribution here through combined heat and power generation. When electricity is generated by turbines, heat is produced that could be utilised via local and district heating networks without generating additional emissions. However, heat is best produced where it is needed. This is another reason why we are researching concepts for small power plants based on micro gas turbines, which could be used to create a decentralised supply structure.

Combustion is considered inefficient by some - so why do we continue to use it?

Power plant and drive systems based on combustion are considered inefficient compared to electrically powered engines. This may be true for vehicles, but the situation is different for power plants thanks to the possibilities of combined heat and power generation. Here, efficiency increases significantly when gas turbines are used as part of such plants or in combination with steam power plants to produce both electricity and heat - see next question. Electrical efficiencies of up to 64 per cent are currently possible here. Neither engines nor fuel cells achieve these values in practice.

How can efficiency be further increased?

Even in power plants that are already highly efficient, the residual heat in the exhaust gas can be utilised to generate heating, local or district heating. This can increase the overall efficiency to over 90 per cent. The utilisation of waste heat is called combined heat and power (CHP). Fuel-flexible CHP plants that run on non-fossil fuels will be needed for a very long time to come - especially in industrial processes that require a lot of process heat and steam on a continuous basis, such as in the pharmaceutical, brewing, paper, glass and chemical industries.