Optical and laser based diagnostics

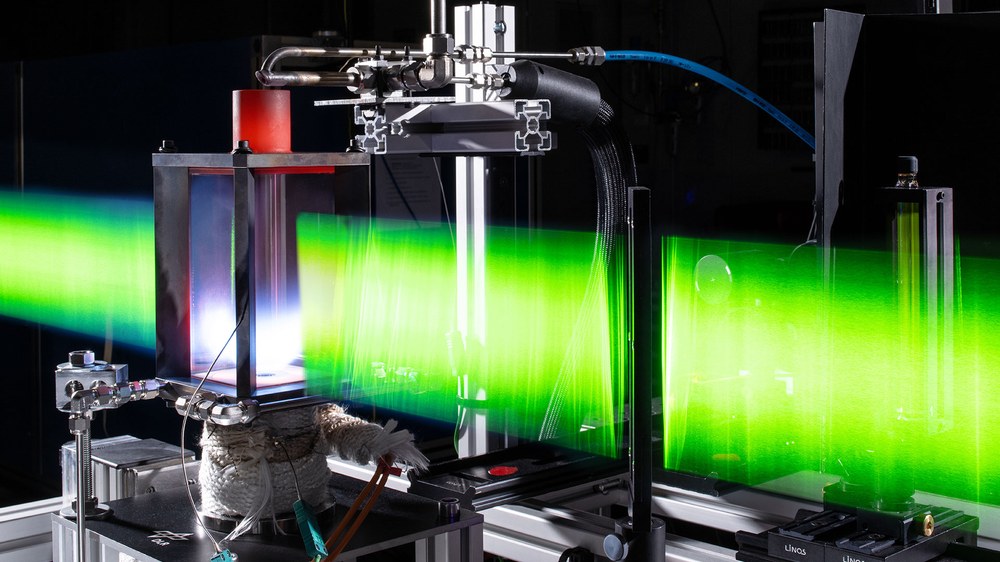

Modern laser diagnostics provide completely new insights into the complex physico-chemical processes that occur during combustion.

In contrast to conventional probes, optical methods enable flame analyses without affecting the flow field in the combustion chamber and the complex physical or chemical processes. Laser diagnostics are non-intrusive, with high spatial and temporal resolution and can also measure two-dimensional distributions when employing light sheets. The methods are employed as single-pulse techniques, i.e. a complete measurement is performed by each individual, extremely short laser pulse, allowing derivation of mean values and statistical fluctuations. These are important prerequisites for resolving the turbulent structures in the combustion zones and obtaining precise information about the combustion process. Quantitative measurement data provide the experimental basis for the verification and further development of numerical simulation models, which are indispensable for an improved evaluation of newly designed combustion concepts with regard to pollutant emissions and the stability of the combustion process.

We are constantly developing the following laser diagnostics in order to use them for a wide range of combustion phenomena:

Rayleigh scattering (density and temperature fields)

Raman scattering (temperatures, species concentrations, mixtures)

Coherent anti-Stokes Raman scattering (CARS, temperatures)

Absorption spectroscopy (species concentrations and temperatures)

Laser-induced fluorescence (LIF, visualisation of flame structures, position of the flame front, 2D temperature fields)

Laser-induced incandescence (LII, 2D soot distributions)

Particle Image Velocimetry (PIV, 2D velocity distributions)

Laser-induced plasma spectroscopy (LIPS, measurement of element composition or minority species)

Phosphor thermometry (determination of surface temperatures)

Beyond this we

use passive optical diagnostics to visualized OH chemiluminescence or spectrally resolve flame emissions

simultaneously use multiple diagnostics

employ a range of laser pulse repetition rates between Hz and kHz according to the research question or project needs (High-speed imaging)

optimize and operate mobile laser diagnostics systems

The measurement methods are not only used in the laboratory, but also at technical rigs such as gas turbine combustors. Investigations on such test objects are carried out on the institute's high-pressure test benches or on site at partners' facilities on behalf of customers. The mobile diagnostics systems mentioned above are available for this purpose. Successful measurements have been performed on

- Segments of gas turbine combustors

- Industrial gas turbine combustors

- Model combustors for rocket propulsion systems

- Industrial combustion systems

- Near-series engines

- Gasification reactors