Atmospheric combustion test benches

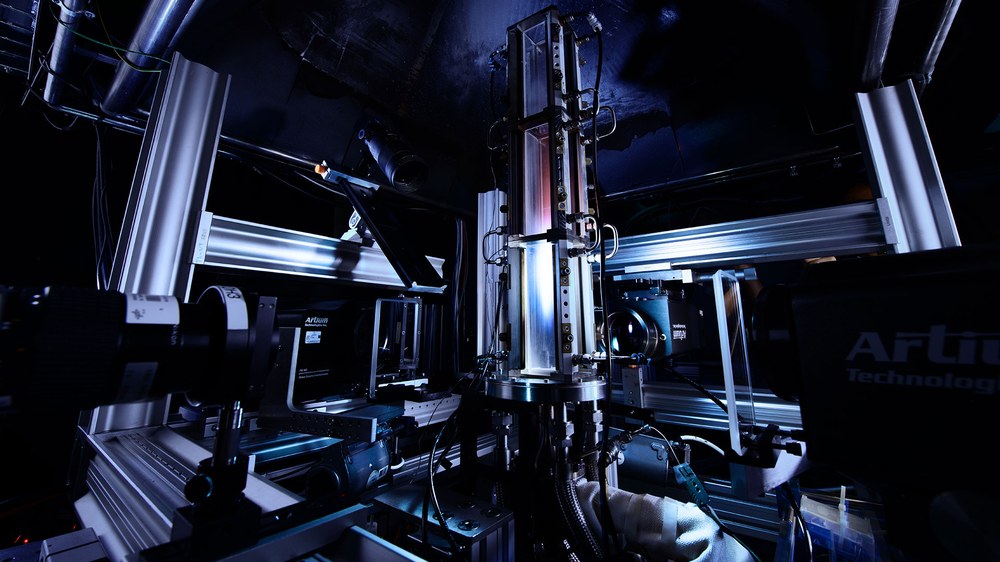

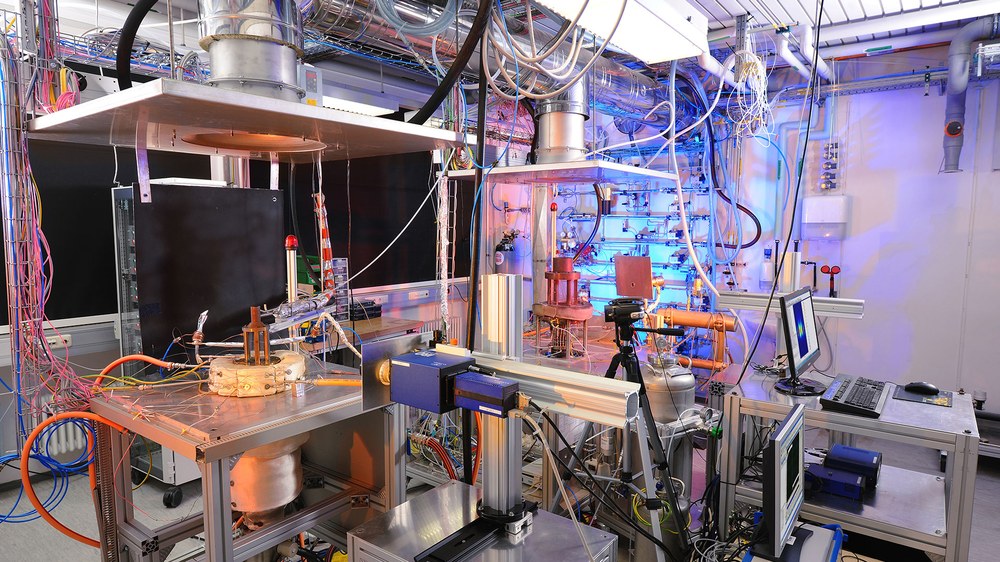

The Institute's atmospheric combustion test benches are used for various purposes: On the one hand, micro gas turbine combustors can be examined under real combustor inlet temperatures and characterised with regard to their general operating behaviour.

Beyond this, some of the test benches are also configured such that combustion phenomena can be analysed in detail with a specific burner/nozzle configuration. A further application is the development and optimization of burner configurations, which subsequently are studied at increased pressure.

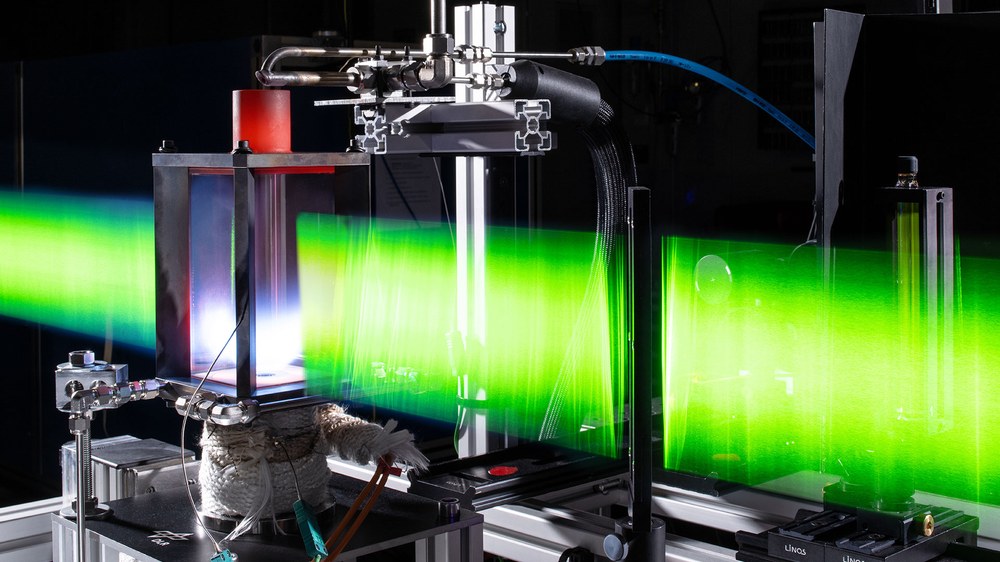

The design of the test benches therefore differs in key respects: The air used for combustion is often heated electrically in order to reach real combustor inlet temperatures of the gas turbine type under study. This can be a few 100 °C up to 800 °C in the case of a recuperated micro gas turbine. Natural gas, kerosene, methanol and other gases such as hydrogen, synthesis gases or wood gas are used as fuels. The combustion process is studied in optically accessible combustion chambers. Here, quartz windows are used as combustor walls instead of metal such that the flame can be closely observed and analysed.

In addition to instrumentation with thermocouples and pressure sensors, the basic measuring equipment usually includes an exhaust gas analyser to detect pollutants, oxygen and carbon dioxide as well as an OH* chemiluminescence camera to detect the shape, distribution and position of the flame. Depending on the scientific research question, numerous other optical or laser-based diagnostics can be employed. For those detailed studies combustors with typical thermal power of 10 - 50 kW are used, typically in jet- or swirl stabilized configurations.