CoBra supports the thermal transition in industry

- Pilot plant in Cottbus reaches temperatures of 300 degrees Celsius – the process heat is sufficient for several industrial sectors.

- High-temperature heat pumps are an alternative to fossil fuels.

- CoBra works with dry air.

- Focus: Energy, digitalisation, technology, heat transition, decarbonisation

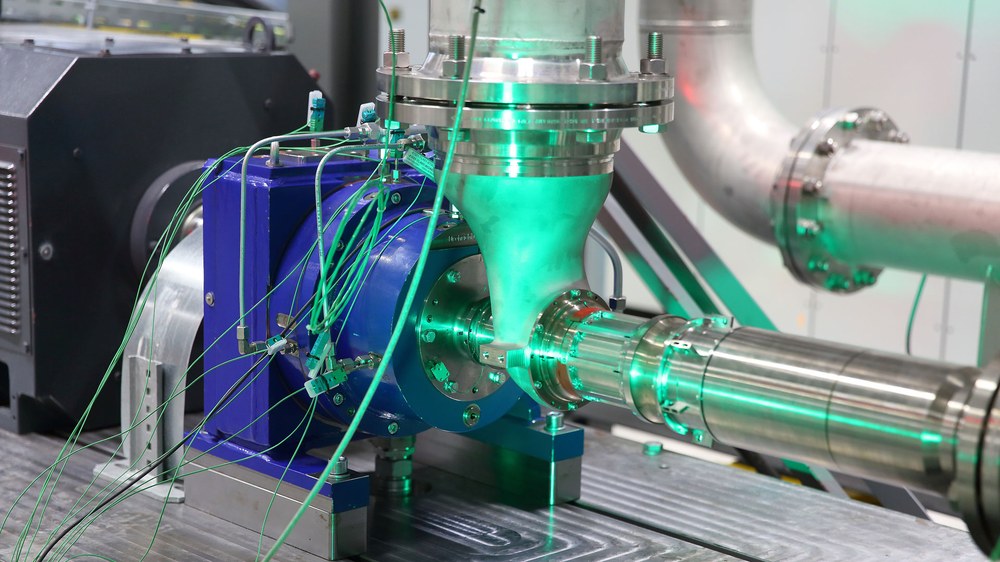

Reducing carbon dioxide emissions while providing heating and cooling for industry – the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is demonstrating how this is possible with a new pilot plant. The CoBra high-temperature heat pump is now going into operation.

The DLR Institute of Low-Carbon Industrial Processes in Cottbus (Brandenburg) is working on technologies and solutions for an energy system of the future that is sustainable and in which industrial companies can manage without using fossil fuels for their production. The CoBra test plant is contributing significantly to the thermal transition in industry: "We can achieve results that are so far unique in the world regarding the temperature range and the heat released at temperatures of up to 300 degrees Celsius with a heat output of about 200 kilowatts," says Institute Director Uwe Riedel. In the future, the aim is to go far beyond this: "The DLR heat pumps will reach a temperature range that has not yet been technically realised. These temperatures are necessary for a low-carbon conversion of the corresponding industrial processes." The name CoBra is a combination of 'Cottbus' and the 'Brayton cycle' the thermodynamic cycle on which the plant is based.

Research drives structural change

The DLR Institute of Low-Carbon Industrial Processes was established at the Cottbus site and has been in operation since July 2019. In close partnership with regional industry and academia, the staff develop technologies for low-carbon processes. With research impulses and innovations, the DLR institute is one of the most important players regarding the structural change in the Lausitz region. "Considering the many challenges of our time, it is nice to see that we as DLR are contributing to solutions with technology transfer from research to industry. CoBra has the potential to enable massive carbon dioxide reductions. At the same time, we create jobs in the region and maintain jobs in Germany as a business location by keeping the production of energy-intensive industries competitive through innovation," says Karsten Lemmer, DLR Executive Board Member responsible for Innovation, Transfer and Research Infrastructure.

Reducing carbon dioxide emissions and saving energy

Most industries require process heat between 100 and 500 degrees Celsius. This is the case, for example, in the food industry, the paper industry and the chemical industry. If electricity generated from renewable sources is used, high-temperature heat pumps are climate-neutral. Industrial companies can also save energy by using high-temperature heat pumps.

The CoBra pilot plant was built within two years; financed with funds from the state of Brandenburg. DLR primarily selected companies from the region for the development and construction of the plant. In the future, another larger CoBra pilot plant will be developed and built, which will allow even higher temperatures and a higher heat output. The CoBra pilot plant currently uses air as the working medium. However, it can also use argon gas. The question of how to scale the prototype so that it is suitable for as many industrial sectors as possible is also at the centre of the research.

This video explains how the CoBra system works.

The DLR Institute of Low-Carbon Industrial Processes in Cottbus and Zittau

In addition to Cottbus, the DLR Institute of Low-Carbon Industrial Processes has a second location in Zittau (Saxony). Research is being conducted on high-temperature heat pumps here as well. The pilot plant ZiRa (the name is a combination of 'Zittau' and 'Rankine process') is currently under construction. It does not work with air, like the CoBra plant, but with water.

In the Department of Simulation and Virtual Design in Cottbus, researchers are developing 'digital twins' of real plants. They provide insights into how renewable energy sources can replace fossil fuels and how industrial processes can be efficiently coupled with other sectors. To do this, solar and wind energy, power plants, storage systems, residential and public buildings and industrial plants must be networked. The department also supports developments on high-temperature heat pumps.

The Department of Low Carbon Reducing Agents in Zittau is investigating how chemical processes can be converted to avoid carbon dioxide emissions. Here, for example, the use of renewably produced hydrogen and other carbon-free energy sources plays a role.

Video – CoBra (2021)

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.