Quality and product assurance for the MMX rover's locomotion subsystem

The mechatronic locomotion subsystem of the Martian Moons eXploration (MMX) mission's robust, wheeled rover IDEFIX is developed from scratch at the DLR Institute of Robotics and Mechatronics in collaboration with the DLR Institute of System Dynamics and Control. Only a few of the components are based on experience gained from previous missions. For this reason, it is essential to demonstrate through rigurous quality and product assurance that this locomotion subsystem will work correctly on the surface of Phobos. The landing gear must proove that it meets all requirements, which were collected based on experience from past space missions as well as those based on assumptions about this particular new mission.

Stress for the locomotion system

The 140 active standards of the European Cooperation for Space Standardization (ECSS) are an essential basis for the requirements of systems and subsystems that will operate in space. This is a European, internationally recognised set of rules that improves the quality and safety an reduces risks of space programmes. At rover level, mission-specific requirements are compiled and adapted from the ECSS. Many of these rover requirements also apply to the locomotion system as a rover subsystem. Requirements specific to the locomotion subsystem are supplemented and – where appropriate – also derived from the ECSS.

Another set of requirements is dervied from the analysis of the rover's overall journey. First, there is a long phase on Earth until the rover has been completely integrated and assembled. Then, it must survive the launch itself atop of an H-3 rocket from the Japan Aerospace Exploration Agency (JAXA). After launch, there is the orbit phase and the journey towards Mars. Finally, the rover will land on the Martian moon Phobos and – after an automatic commissioning phase – it will explore the surface.

During this journey, the landing gear will be subjected to a number of loads and stresses:

• Tests on Earth

• Strong vibrations and heat during the launch of the rocket

• Hot and cold phases as well as exposure to radiation during the flight to Phobos

• Impact on Phobos during landing

• Hot and cold phases as well as exposure to radiation on Phobos itself

These loads and stresses are anticipated and used to determine the requirements for the locomotion subsystem that must be taken into account during its development. Additional requirements arise from the interfaces to and interaction with the rover's other components. This means that in addition to basic technical regulations, more than 120 mission-specific requirements must be met.

Every screw counts

Among others, the system requirements include quality and product assurance for processes, the use of certain products and materials, documentation, manufacturing and the testing itself. A critical factor is the avoidance of certain materials that can be destroyed or severely impair the function of other components through outgassing under vacuum conditions or as a result of radiation. Adhesives are an example of this.

In addition, the maximum permissible weight of the rover – and thus also the share of the landig gear in the total weight – must be taken into account. The specified weight of the landing gear must be broken down to individual components, for example screws.

Simulation of the mission

Early on, verification that the landing gear meets the requirements is accomplished using analyses or design reviews. It is additionally confirmed during tests of individual components. Furthermore, qualification and acceptance tests are performed on the complete landing gear.

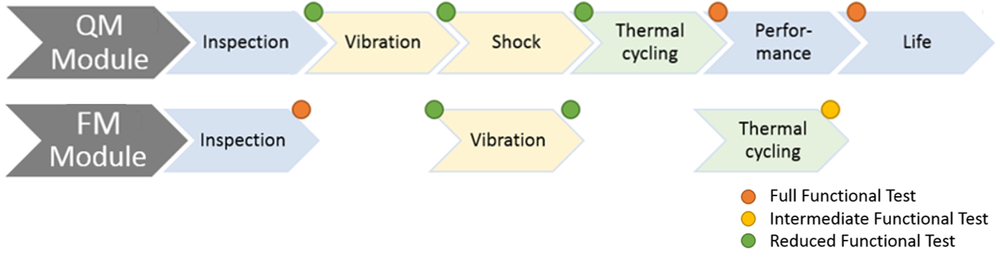

A dedicated model of the landing gear is built for the qualification tests, this model is subjected to the high loads and stresses expected during the journey. The acceptance tests are carried out on the flight model – the hardware that will actually embark on the long journey. In order not to stress the flight hardware unnecessarily before the journey, it is subjected to lower loads than are expected on the journey. Since the qualification model and the flight model are almost identical in construction, it can be assumed that the flight model also meets all requirements.

According to the ECSS standard and the mission analysis, the models are exposed to vibrations, impact shocks as well as hot and cold temperatures (thermal cycling). Then, the performance is tested. To ensure that the landing gear will function for the entire duration of the mission, tests are also carried out on the qualification model to simulate the entire mission duration on Phobos (live tests). Fewer tests are carried out on the flight model.

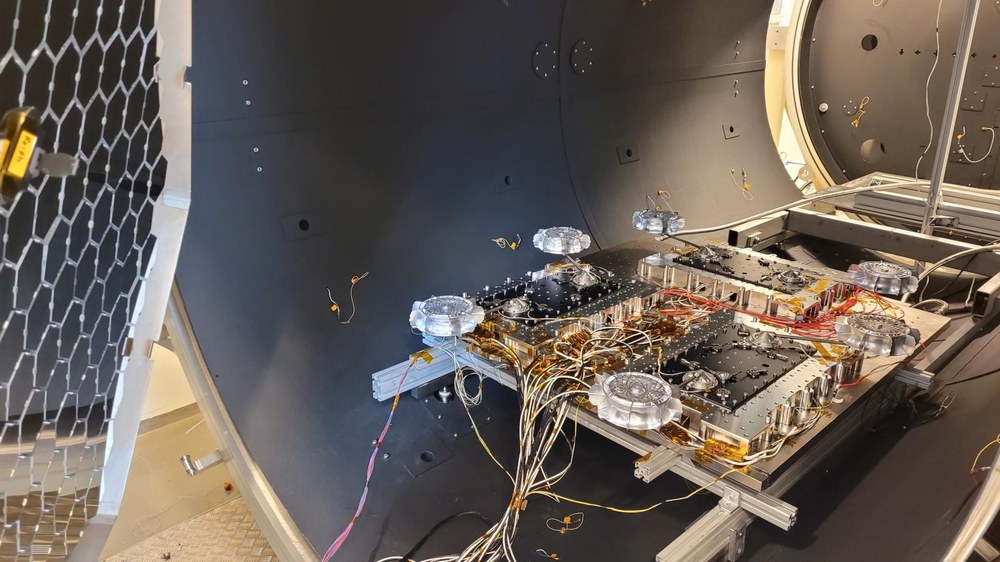

In order to subject the qualification model and the flight model to the necessary stresses, the hardware is for example enclosed in a thermal vacuum chamber for tests such as the thermal cycling tests. Under vacuum conditions, it is then heated up and cooled down several times to the desired temperature.

Additional inspections, reviews and functional evaluations are conducted before and after each test. This ensures a common understanding of the test objectives and requirements, the measuring and testing equipment used and the test setup across all DLR institutes and external partners involved. This can also help ensure that in the event of deviations, possible causes can be quickly identified and eliminated and that any risks are communicated to the project management for evaluation.

Continuous improvement

Deviations from requirements and failed tests must be documented and tracked in the form of non-conformance reports. Solutions that introduce as little risk to the mision as possible must be found for these deviations. Either the affected components will be revised, the risks will be (re)assessed or, if necessary, the requirements will be checked again and adapted. The sum of these measures ensure that the DLR Institute of Robotics and Mechatronics has provided a landing gear that will make a significant contribution to the success of the MMX mission.

MMX – Martian Moons eXploration

MMX is a mission of the Japanese space agency JAXA with contributions from NASA, ESA, CNES (the French space agency) and DLR. CNES (Centre National d'Études Spatiales) and the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) are jointly contributing a 25-kilogram rover to the Martian Moons eXploration Mission (MMX). The Franco-German MMX rover is being designed and built under the joint leadership of CNES and DLR. In particular, DLR is responsible for the development of the rover's landing gear, including the lightweight body, as well as the entire uprighting and locomotion system. DLR is also contributing the connection adapter to the MMX spacecraft and providing a Raman spectrometer and a radiometer as scientific experiments. These will analyse the surface composition and texture on Phobos. CNES is making significant contributions with camera systems for spatial orientation and exploration on the surface, as well as for the study of mechanical soil properties. CNES is also developing the rover's central service module, including the on-board computer and the power and communications system. After the launch of the MMX mission, the rover will be operated by CNES control centres in Toulouse (France) and DLR in Cologne (Germany).

For DLR, the institutes of System Dynamics and Control, Composite Structures and Adaptive Systems, of Space Systems, of Optical Sensor Systems, of Planetary Research, for Software Technology and the Microgravity User Support Center (MUSC) are also involved under the leadership of the DLR Institute of Robotics and Mechatronics.

The MMX mission is a continuation of an already long-standing successful cooperation between JAXA, CNES and DLR. It builds on the previous mission Hayabusa2, in which JAXA sent a spacecraft to the asteroid Ryugu with the German-French MASCOT lander on board. On 3 October 2018, MASCOT landed on Ryugu and sent spectacular images of a landscape ridden with boulders and rocks, and virtually no dust. Hayabusa2 collected samples from Ryugu and brought them to Earth on 6 December 2020.